|

|

Expert 5K+

Posts: 9654

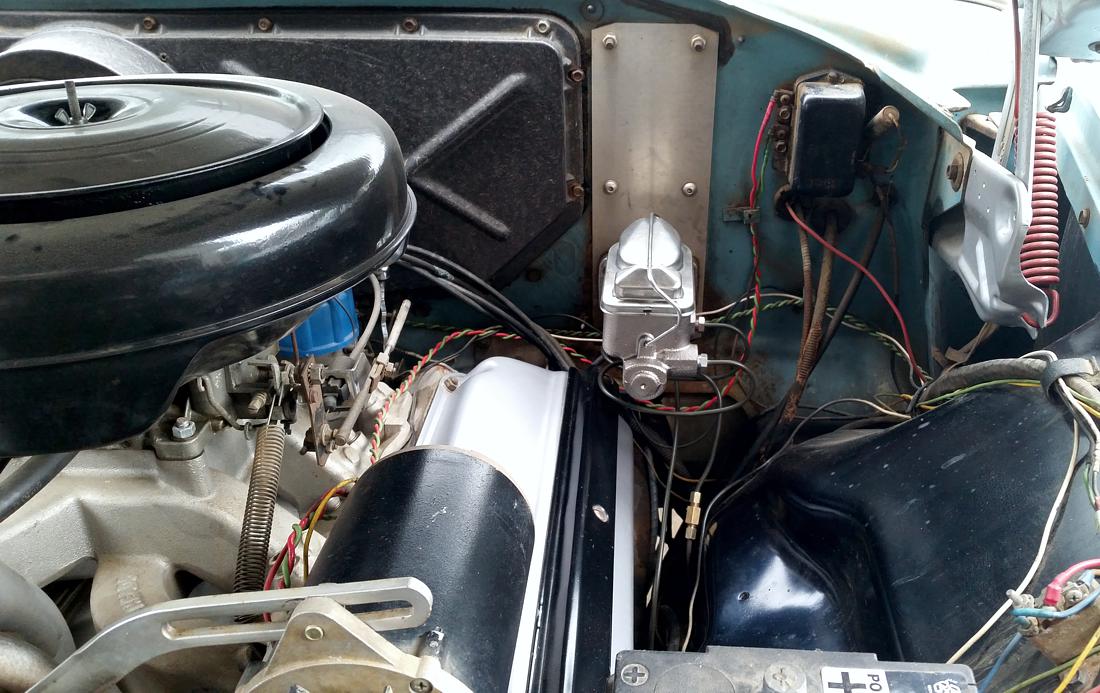

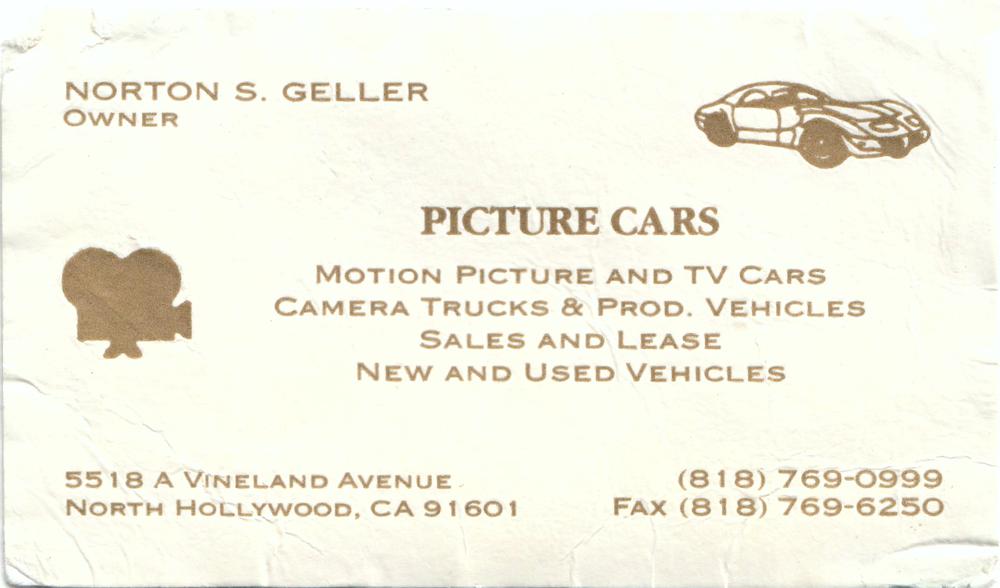

Location: So. Cal | I decided to start a thread on my '56 Plymouth so that I have a central spot to show what I am doing with it. I bought the car in 2003 from "Picture Cars" in Burbank, which is a company that rents cars out to movie studios. This car brought me to the forwardlook email group at that time. I believe that one year later in 2004, the list moved to the Forum format. The car had it's original 277 poly V8 and powerflite transmission and I was just barely able to drive it home after some tweaking of the carb & timing. An electronic ignition upgrade and other fixes turned the car into reliable running car that got 17 mpg at 50mph. My quest for a cheap & better electronic ignition setup for this car drove me to create & sell the GM HEI conversion that I continue to sell today.

Edited by Powerflite 2015-06-04 7:36 PM

(RtFront.jpg) (RtFront.jpg)

(RtRear.jpg) (RtRear.jpg)

(My 277 Motor.jpg) (My 277 Motor.jpg)

Attachments

----------------

RtFront.jpg (38KB - 706 downloads) RtFront.jpg (38KB - 706 downloads)

RtRear.jpg (27KB - 696 downloads) RtRear.jpg (27KB - 696 downloads)

My 277 Motor.jpg (110KB - 729 downloads) My 277 Motor.jpg (110KB - 729 downloads)

|

|

| |

|

Expert 5K+

Posts: 9654

Location: So. Cal | The 277 motor ran pretty well for as old as it was, but it began to leak quite a bit of oil from the rear main seal so I decided it was time to swap to a hemi motor. I had originally purchased the car with the intent to get a car that I wanted to put the 392 hemi into that I had installed into a '68 Barracuda as a 16 yr old kid. I didn't like the way it fit in the Cuda so I wanted a car that it would fit into better, but still be able to hotrod around in.

Edited by Powerflite 2015-06-04 6:21 PM

(392HemiOutof68Cuda.jpg) (392HemiOutof68Cuda.jpg)

Attachments

----------------

392HemiOutof68Cuda.jpg (101KB - 722 downloads) 392HemiOutof68Cuda.jpg (101KB - 722 downloads)

|

|

| |

|

Expert 5K+

Posts: 9654

Location: So. Cal | I don't know why I tore it apart because the 392 motor ran pretty well, but I tore it down and purchased a running 331 hemi from a '55 Imperial, straight from Memory Lane wrecking yard, and threw that into the Savoy. To get it to fit, I had to:

1. Make my own lower motor mounts ( the original V8 mounts would have worked, but they interfered with the exhaust I ended up using). The upper portion I purchased from PAW, now R.I.P.

2. Move the motor & trans over to the left 1 inch

3. Install a '57 392 center sump oil pan & pickup

4. Swap the header pipes around on the Chinese shorty headers.

Then it fit like a glove with only 1/4" extra height on the motor mounts just to clear the header pipes a little better. Custom headers would be ideal, and those are still in the plans.

You can see the old thread on it here:

http://www.forwardlook.net/forums/forums/thread-view.asp?tid=13584&...

Edited by Powerflite 2015-06-04 8:47 PM

(Left.jpg) (Left.jpg)

(Exhaust.jpg) (Exhaust.jpg)

(Hemi.jpg) (Hemi.jpg)

Attachments

----------------

Left.jpg (56KB - 695 downloads) Left.jpg (56KB - 695 downloads)

Exhaust.jpg (90KB - 725 downloads) Exhaust.jpg (90KB - 725 downloads)

Hemi.jpg (75KB - 741 downloads) Hemi.jpg (75KB - 741 downloads)

|

|

| |

|

Expert 5K+

Posts: 9654

Location: So. Cal | The hemi had a lot of rust built up inside its passages so I filled the motor with a dissolved solution of Cascade automatic dish soap and ran the motor around (plugged hose to hose) without a fan or radiator until it was hot. Then I let it sit overnight, got it hot again, and dumped it. Amazing how well that worked. The water was thick with brown rust. After a couple of good flushings, it was good to go.

The motor added some weight to the car so it didn't handle as well as it used to so I decided to install a sway bar from a '56 Chrysler that was 7/8" instead of the 3/4" Plymouth bar. It was a little wider than the Plymouth, but it worked and made the car handle similar to the way it did before.

Edited by Powerflite 2015-06-04 7:25 PM

(ChryslerSwayBar.jpg) (ChryslerSwayBar.jpg)

Attachments

----------------

ChryslerSwayBar.jpg (42KB - 692 downloads) ChryslerSwayBar.jpg (42KB - 692 downloads)

|

|

| |

|

Expert 5K+

Posts: 9654

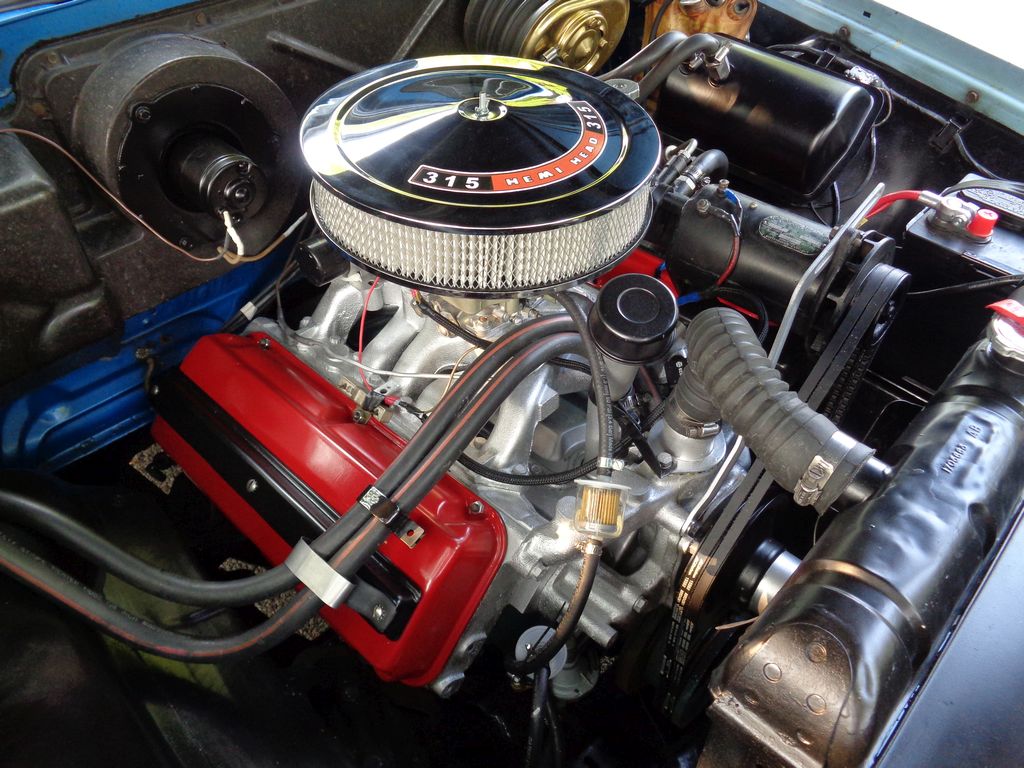

Location: So. Cal | Time passed and I drove the car for 2-3 years, often commuting with it 90 miles roundtrip, but it eventually started to smoke - really bad. It became so bad that just moving it across the street would hinder the visibility for a 1/2 mile or so just getting it out of my driveway. Not good. I wish I had thought to take a movie or picture of it. It was spectacular. I quickly determined that the problem had nothing to do with the valve seals. Great, so the rings are bad. So it sat while I gussied up the 392 I wanted to put into it. I purchased aluminum heads for it, and bumped up the compression to 11:1, put in a nice cam and upgraded to a GM alternator.

But now I wish I had tried to make it look more stock. This motor is going to really ruin the nostalgic factor of my Plymouth. Too much bling on it, but I do like how light it is. I need to find a good compromise.

Edited by Powerflite 2015-06-04 7:06 PM

(Hemi Alt Mounted.JPG) (Hemi Alt Mounted.JPG)

Attachments

----------------

Hemi Alt Mounted.JPG (88KB - 703 downloads) Hemi Alt Mounted.JPG (88KB - 703 downloads)

|

|

| |

|

Expert 5K+

Posts: 9654

Location: So. Cal | I decided to replace the rear axle & transmission while I was at it so I welded up spring mounts at 41" apart on a '68-'70 B-body axle with the shock mount placed in the back end of the spring mounts like the originals. I used the remains of the old B-body mounts to ensure that the new mounts would be welded on at the same pinion angle.

But looking back, I should have used the '65-'67 B-body axle I had laying around instead because there is a little too much offset required with this axle. Also, I should have used the original spring mounts from the '56 rear because they need to be very narrow in order to fit well on the splayed springs. But, it worked out in the end.

Edited by Powerflite 2015-06-04 7:02 PM

(56PlymRear.jpg) (56PlymRear.jpg)

Attachments

----------------

56PlymRear.jpg (130KB - 1806 downloads) 56PlymRear.jpg (130KB - 1806 downloads)

|

|

| |

|

Expert 5K+

Posts: 9654

Location: So. Cal | At the end of 2014, I was finally ready to pull the 331 out and put the 392 into it's place. As I unbolted the exhaust, oil literally dripped out of it. Wow, that's a lot of oil in there. Then I drained the oil, and to my amazement, about 12 qts of oil came out of that motor! When I originally installed the motor, I didn't have the right dipstick for the 392 pan. So I used an aftermarket one and filled the motor and marked the stick with the oil that was on it. But it was registering on some puddle in the tube.  I ended up lengthening the dipstick a good 5 inches to get it in the right spot. I ended up lengthening the dipstick a good 5 inches to get it in the right spot.

Once I had the right amount of oil in the car, I started it up and it blew a big puddle of oil from the open headers onto my driveway and instantly lit it on fire! That was pretty fun. Fortunately, the car was up on jack stands and the fire didn't do any harm. After I burned out all the oil in my mufflers, the car ran without smoking at all! So I put off swapping in the 392 for the time being and left the 331 in there.

Edited by Powerflite 2015-06-04 8:52 PM

|

|

| |

|

Expert

Posts: 2312

Location: Arizona | One of the cars I restored was a 69 Firebird. The bottom dipstick tube had fallen into the pan and the end of the dipstick was no longer "aimed" in the right spot. I drained almost 8 quarts out of it's 6 quart crankcase. People had just kept adding oil till it hit the no longer properly aimed dipstick. |

|

| |

|

Expert 5K+

Posts: 9654

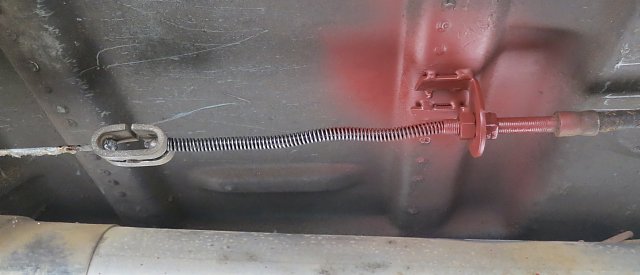

Location: So. Cal | I decided to go forward with the transmission upgrade since I was in between jobs and had more time on my hands. So I pulled the powerflite trans and installed a 700R4 overdrive. I had devised a way to shift it with the original push buttons, but eventually I decided to use the car for towing a camping trailer around and I needed access to 1st and 2nd gear. So I shift it with a cable mounted next to the steering column for the time being. In order to accomplish the transmission swap I needed to:

1. Cut the trans crossmember and move the mount back 2 inches.

2. Use a B-body driveshaft with a GM slip yoke (cut to length) on the end of it.

3. Use a radiator with a trans cooler in it. Fortunately, mine already had them.

4. Route cooling lines and shifter brackets.

5. Use a converter lockup unit from Ron Francis wiring and wire it up to the brake switch etc.

6. Hook up the E-brake to the rear axle by using a small connector cable & mount.

7. Mount & adjust the kickdown cable to the throttle linkage.

You can see the original thread about it here:

http://www.forwardlook.net/forums/forums/thread-view.asp?tid=56159&...

Edited by Powerflite 2015-06-04 11:26 PM

(700R4Trans.jpg) (700R4Trans.jpg)

(FrontCableConnection.jpg) (FrontCableConnection.jpg)

(CableRearConnection.jpg) (CableRearConnection.jpg)

Attachments

----------------

700R4Trans.jpg (47KB - 701 downloads) 700R4Trans.jpg (47KB - 701 downloads)

FrontCableConnection.jpg (28KB - 713 downloads) FrontCableConnection.jpg (28KB - 713 downloads)

CableRearConnection.jpg (34KB - 673 downloads) CableRearConnection.jpg (34KB - 673 downloads)

|

|

| |

|

Expert 5K+

Posts: 9654

Location: So. Cal | Yeah Jim, not one of the brighter moments in my life. To think that I let the car sit for many years thinking the motor was gone, when it just needed the right amount of oil.  |

|

| |

|

Expert 5K+

Posts: 9654

Location: So. Cal | I wanted to drive my car around again, but the paint had become badly oxidized from sitting in the California sun. It was pretty bad. So I wet sanded the old paint and painted a white '56 Fury stripe on the side like I had always wanted to do. then I painted the whole car with a coat of clear.

('56Stripe.jpg) ('56Stripe.jpg)

(56NewLook.jpg) (56NewLook.jpg)

(56NewLookBack.jpg) (56NewLookBack.jpg)

Attachments

----------------

'56Stripe.jpg (90KB - 695 downloads) '56Stripe.jpg (90KB - 695 downloads)

56NewLook.jpg (78KB - 677 downloads) 56NewLook.jpg (78KB - 677 downloads)

56NewLookBack.jpg (59KB - 708 downloads) 56NewLookBack.jpg (59KB - 708 downloads)

|

|

| |

|

Expert 5K+

Posts: 9654

Location: So. Cal | I bit the bullet and installed 3-point seatbelts so I would feel good about driving it around on a more regular basis. A sedan is much easier for doing this then a hardtop, but it required a lot more work than I expected because there really wasn't a lot of reinforcement designed into the B & C pillars. I had to add a lot of structural metal to the backsides of the inner body to be able to secure a good mount there. I used 3/16" plate cut & bent to the shape of the inside sheet metal and another 3/16 plate behind that to put the mount into. I welded a nut on the backside of the plate and another one on the front with threads in between all lined up to each other.

I wanted to install a retractable seatbelt in the back seat as well, but I needed to modify the seat frame to keep it from pinching the belt and give it enough room to move freely. I didn't want to do that right now so I installed fixed belts for the time being. I also would have used more classic chrome buckles that are available now to better match the '50's style. But I had already purchased these belts a long time ago and will use them until I get tired of them.

My original seats had become ripped and sun-rotted so my wife and I installed some gray "Zink" seat covers on them. These seat covers are cheap and won't last long, but I keep a sacrificial cloth over the back seat area to protect them from the sun through the back window. Hopefully that will make them last long enough to give me time to figure out what I really want to do with the seats. We also replaced the carpet while we were at it. The headliner is next, hopefully soon.

Edited by Powerflite 2015-06-04 10:49 PM

(RRUpperMount.jpg) (RRUpperMount.jpg)

(RFUpper Mount.JPG) (RFUpper Mount.JPG)

(56Seats.jpg) (56Seats.jpg)

Attachments

----------------

RRUpperMount.jpg (48KB - 719 downloads) RRUpperMount.jpg (48KB - 719 downloads)

RFUpper Mount.JPG (104KB - 714 downloads) RFUpper Mount.JPG (104KB - 714 downloads)

56Seats.jpg (95KB - 732 downloads) 56Seats.jpg (95KB - 732 downloads)

|

|

| |

|

Expert 5K+

Posts: 9654

Location: So. Cal | I recently installed a hitch to tow our camping trailer. My mother-in-law's neighbor threw this hitch to the curb for garbage collection, so of course I grabbed it.  I don't know what it went to, but it is wider than the typical hitch and was a near perfect match for the '56 Plymouth. The only problem was that it hung too low. So I cut the horizontal mount off and lowered it by 3-4 inches. It is mounted to the bottom of the frame at 3 points on each side. You can't see it in the picture, but I also mounted it to the side of the frame at one point that already had a nut in place for the front-most bumper mount. I don't know what it went to, but it is wider than the typical hitch and was a near perfect match for the '56 Plymouth. The only problem was that it hung too low. So I cut the horizontal mount off and lowered it by 3-4 inches. It is mounted to the bottom of the frame at 3 points on each side. You can't see it in the picture, but I also mounted it to the side of the frame at one point that already had a nut in place for the front-most bumper mount.

I also added 2 extra leafs to each of the springs so that they could handle the weight. They made the ride a little more harsh when it is empty, but not by much. The car no longer sags when it is loaded like it used to.

Edited by Powerflite 2015-06-05 12:20 AM

(UnderHitch.jpg) (UnderHitch.jpg)

Attachments

----------------

UnderHitch.jpg (88KB - 708 downloads) UnderHitch.jpg (88KB - 708 downloads)

|

|

| |

|

Exner Expert 19,174 posts. Neil passed away 18 Sep 2015. You will be missed, Neil!

Posts: 19146

Location: bishop, ca | Nathan....do you happen to have both of the cast iron exhaust manifolds, seen above?

|

|

| |

|

Expert 5K+

Posts: 9654

Location: So. Cal | I do, why? I am planning to use them in my '57 Windsor. I am hoping I can use them unmodified with a 392 since the car has manual steering. |

|

| |

|

Expert

Posts: 2196

Location: Muskego, WI | The exhaust manifold is the more desirable square flange with 4 bolt holes, I believe those were used on trucks and 300s only. |

|

| |

|

Expert 5K+

Posts: 9654

Location: So. Cal | I purchased some new tires & wheels for the car. I didn't care for the way whitewalls looked on this car. And I wanted a wider tire with a smaller sidewall that was about the same height as the originals and could take the original Plymouth dog dish caps. So I decided to go with 17" aluminum rims to keep the weight reasonable. These are Centerline "Elite" wheels. I had a machine shop drill & tap (3) 1/4-20 holes into each wheel, evenly spaced at a 9.5" diameter circle around the hub. I then took some stainless flathead screws and ground the outside diameter of the head down to round it up more and inserted those into the wheel to mount the caps onto them. the angled portion of the flathead makes it easier to pop the caps back off and grinding it down makes it easier to get it to go on.

I really like them, but I think I would like them better if they were painted black. The extra color is a little too much for me. The tires are 225/55/17 on 7" rims in the front and 235/60/17 in the back with 8" rims. I was originally going with 245/55/17 in the back, but it was in danger of rubbing the fender and they are a lot more expensive. The way the car drives & handles is like night and day. So much better now.

(SavoyTiresRear.jpg) (SavoyTiresRear.jpg)

(Savoy TiresLR.jpg) (Savoy TiresLR.jpg)

(SavoyTiresFrt.jpg) (SavoyTiresFrt.jpg)

Attachments

----------------

SavoyTiresRear.jpg (152KB - 686 downloads) SavoyTiresRear.jpg (152KB - 686 downloads)

Savoy TiresLR.jpg (145KB - 693 downloads) Savoy TiresLR.jpg (145KB - 693 downloads)

SavoyTiresFrt.jpg (193KB - 689 downloads) SavoyTiresFrt.jpg (193KB - 689 downloads)

|

|

| |

|

Expert

Posts: 2119

Location: atlanta | Nice ride, lottta work, but Your there now, congrats. |

|

| |

|

Expert 5K+

Posts: 9654

Location: So. Cal | Thanks Roger, if only that were true  The motor has been running since '55 without a rebuild and really should be replaced with a strong & lightened 392. It will likely never happen while this one keeps ticking on. But even if it is no hotrod yet, it has definitely come to the point that it is very enjoyable to drive and use, just like yours. So here's (glass raised) to enjoying them! The motor has been running since '55 without a rebuild and really should be replaced with a strong & lightened 392. It will likely never happen while this one keeps ticking on. But even if it is no hotrod yet, it has definitely come to the point that it is very enjoyable to drive and use, just like yours. So here's (glass raised) to enjoying them! |

|

| |

|

Location: North Australia | In my opinion the new wheels and tyres really suit your car. They look great! In fact the whole look of your car is pretty exceptional. well done creating a unique car.

Steve.

|

|

| |

|

Expert 5K+

Posts: 9654

Location: So. Cal | Thanks Steve!  |

|

| |

|

Expert 5K+

Posts: 9654

Location: So. Cal | For future reference, I looked up the part number on the hitch that I used on this car. It is a Towing Products or Reese No. 51024 which is made for a '97-'02 Lincoln Navigator or Ford Expedition.

Also I should list the backspacing on the wheels that I used. The front wheels have 4" backspacing on 7" wheels which give 0 offset. The rear wheels are 8" with a 5" backspace that results in a +1/2" offset. This is with the '68-'70 B-body rear axle. |

|

| |

|

Expert

Posts: 2196

Location: Muskego, WI | I think the tires and wheels (and the car in general) look really sharp. |

|

| |

|

Expert

Posts: 3033

Location: N.W. Fla. | Powerflite - 2016-03-04 11:22 PM

But even if it is no hotrod yet, ! With the 331 Chr in it, it is a hot rod!  |

|

| |

|

Expert

Posts: 3033

Location: N.W. Fla. | Powerflite - 2015-06-04 5:48 PM

But now I wish I had tried to make it look more stock. This motor is going to really ruin the nostalgic factor of my Plymouth. Too much bling on it, but I do like how light it is. I need to find a good compromise. Well...ditch the cheezy looking fake "bug catcher", put on an OEM water crossover, & adding a coat of Plastikote would go a long way to solving that problem. Ditch the Fram also & get a Wix. |

|

| |

|

Elite Veteran

Posts: 792

Location: Buena Park, CA | The new wheels and tires look great Nathan.

Edited by DepsilonD 2016-03-10 5:36 PM

|

|

| |

|

Expert 5K+

Posts: 7806

Location: Williams California | Very cool!! |

|

| |

|

Expert 5K+

Posts: 9654

Location: So. Cal | Thanks guys, I'm starting to warm up to the color on them now too.

George, that motor is now slated to go into my '58 New Yorker so it is going back to mostly stock form... I think. Unfortunately, I can't use a stock crossover with those heads because it won't fit. But I am thinking of cutting up a stock one and lengthening it to make it work, but it isn't easy to do if you want to keep the generator mount in the right spot. But I'll give it a shot when I get time to play with it. |

|

| |

|

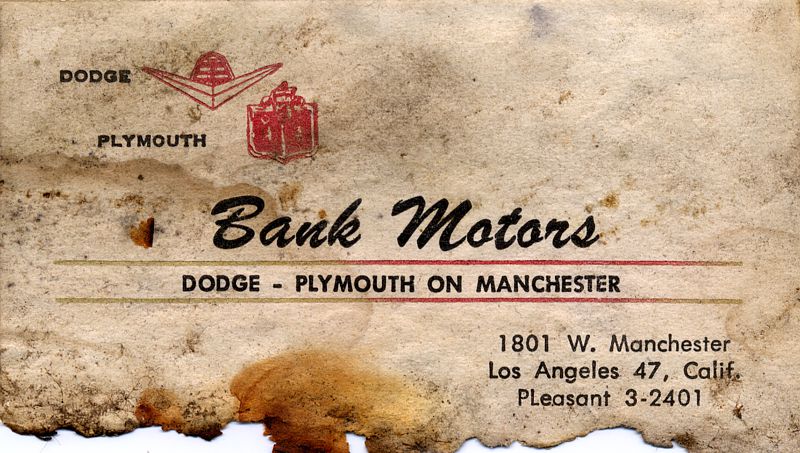

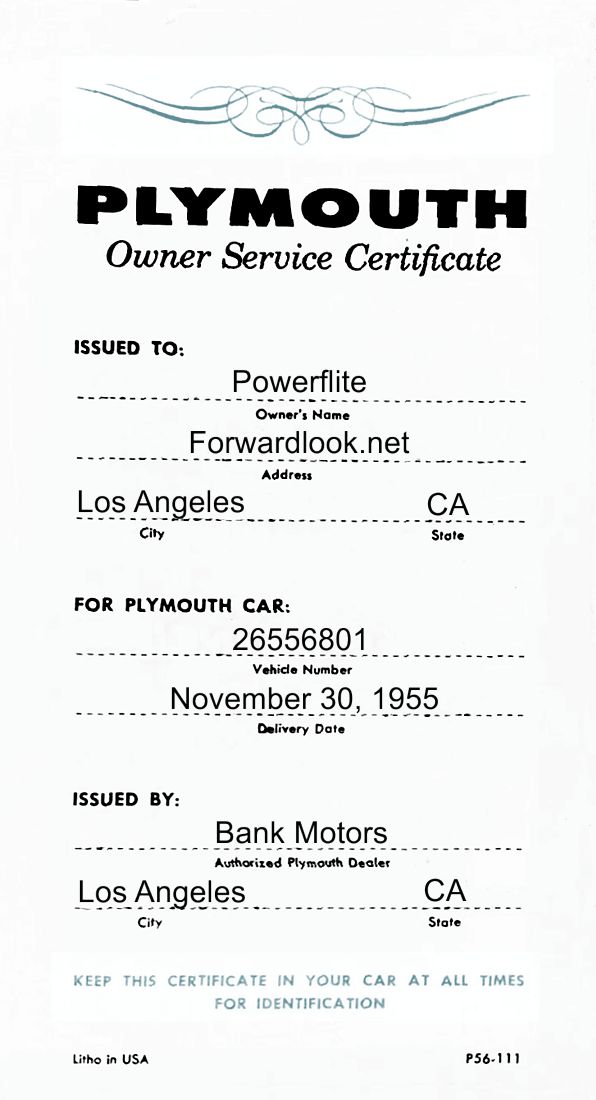

Expert 5K+

Posts: 9654

Location: So. Cal | This is a business card of the car dealer that the 2nd previous owner bought the car from. I know that this company went out of business quite a while ago because I can't find any ads from them beyond the mid 60's. I am not sure if he bought it from them new or used, but it looks like they specify just Dodge and Plymouth so it sounds like a new car dealership. Is that PLeasant 3-2401 an old type of phone number?

Edited by Powerflite 2016-03-31 2:22 AM

(Bank MotorsCard.jpg) (Bank MotorsCard.jpg)

Attachments

----------------

Bank MotorsCard.jpg (111KB - 670 downloads) Bank MotorsCard.jpg (111KB - 670 downloads)

|

|

| |

|

Expert 5K+

Posts: 9654

Location: So. Cal | I was always planning to run dual quads on a 392 hemi for this car. Now I am thinking a single 4 with an original air cleaner would be better. I am even thinking that I may go with a 354 stroker @ 412 cubic inch just to keep it all '56 instead. That's probably more in line with it's current use for pulling my camping trailer & family outings. So I cut up the original air cleaner I had and welded a large 4bbl rim to it from the inside so I could run it with a fuel injection throttle body or a Fi-Tech setup. Watch out when you cut the lids on these things. If you catch the inside on fire, you get to smell what 60 year old burnt horse hair smells like.

(Air Cleaner Base.jpg) (Air Cleaner Base.jpg)

Attachments

----------------

Air Cleaner Base.jpg (149KB - 610 downloads) Air Cleaner Base.jpg (149KB - 610 downloads)

|

|

| |

|

Expert 5K+

Posts: 9654

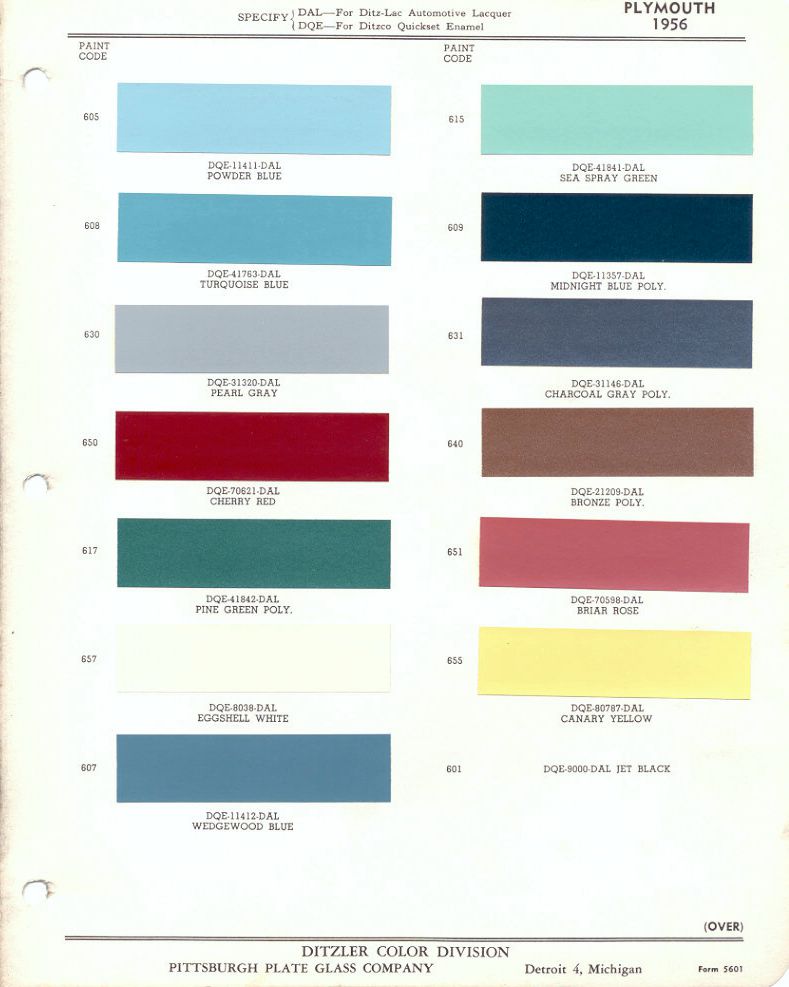

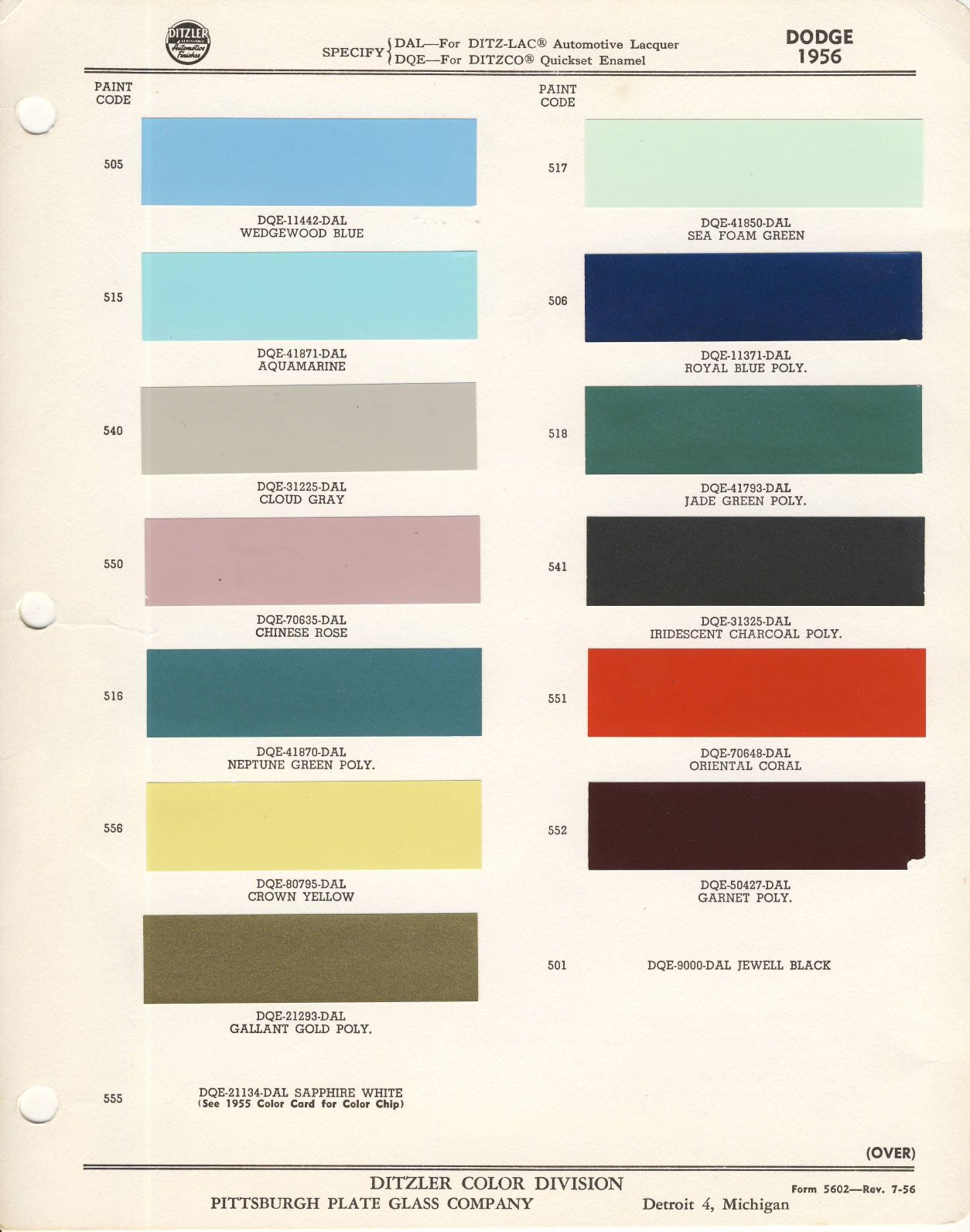

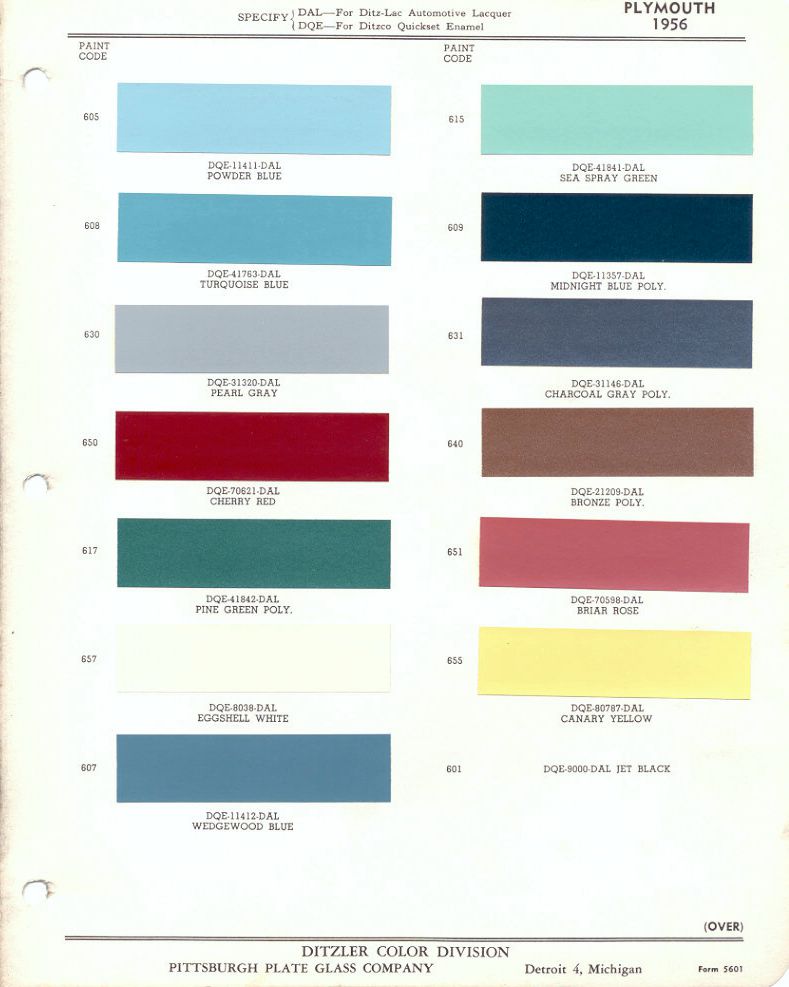

Location: So. Cal | This is the first time I have looked at this tag even after owning the car for 15 years.  Weird that it says 607: wedge-wood blue paint. The paint on the firewall, which has got to be original, is much lighter than that, as is the paint on the underside, C-pillars & roof in the previous pictures. I had always assumed that it was painted a powder blue or turquoise blue. Does anyone know what a 505 trim looks like? I have some of the original fabric on the seats still, but now I am wondering what is original and what isn't. Since the tag is mounted with regular screws, I guess it is possible that the tag has been replaced, but that doesn't make a lot of sense either. Weird that it says 607: wedge-wood blue paint. The paint on the firewall, which has got to be original, is much lighter than that, as is the paint on the underside, C-pillars & roof in the previous pictures. I had always assumed that it was painted a powder blue or turquoise blue. Does anyone know what a 505 trim looks like? I have some of the original fabric on the seats still, but now I am wondering what is original and what isn't. Since the tag is mounted with regular screws, I guess it is possible that the tag has been replaced, but that doesn't make a lot of sense either.

Edited by Powerflite 2017-10-03 10:51 AM

(56PlymBodyTag.jpg) (56PlymBodyTag.jpg)

(56FirewallColor.jpg) (56FirewallColor.jpg)

(1956_plymouth_ppg_c_01.jpg) (1956_plymouth_ppg_c_01.jpg)

Attachments

----------------

56PlymBodyTag.jpg (124KB - 612 downloads) 56PlymBodyTag.jpg (124KB - 612 downloads)

56FirewallColor.jpg (153KB - 614 downloads) 56FirewallColor.jpg (153KB - 614 downloads)

1956_plymouth_ppg_c_01.jpg (74KB - 605 downloads) 1956_plymouth_ppg_c_01.jpg (74KB - 605 downloads)

|

|

| |

|

Expert 5K+

Posts: 9900

Location: Lower Mainland BC | Interesting. I doubt that the tag has been replaced.

My 56 Dodge lower paint is Wedgewood blue but it looks a lot lighter than yours. Paint codes are NOT the same (DQE- 11442- DAL for mine, DQE- 11412- DAL for yours). My firewall is the darker Royal Blue Poly.

The more I look at yours, I would say it is the original Plymouth version of Wedgewood blue (607).

Edited by 56D500boy 2017-10-03 1:55 PM

|

|

| |

|

Expert 5K+

Posts: 9654

Location: So. Cal | Interesting that Dodge calls it the same color, but is a much lighter shade. |

|

| |

|

Expert 5K+

Posts: 9654

Location: So. Cal | I got the filter elements and decal for the 4bbl air cleaner and put it all together. Not sure if super glossy is the look I wanted, but I'll go with it for now. If I re-do it, I may try a semi-gloss instead. But this should look a lot better than that Moroso air cleaner that I had on there.

Edited by Powerflite 2017-11-11 11:20 AM

(56AirCleaner.jpg) (56AirCleaner.jpg)

Attachments

----------------

56AirCleaner.jpg (220KB - 596 downloads) 56AirCleaner.jpg (220KB - 596 downloads)

|

|

| |

|

Expert 5K+

Posts: 9900

Location: Lower Mainland BC |

Powerflite - 2016-03-31 2:19 AM Is that PLeasant 3-2401 an old type of phone number?

P = 7 and L = 5 so the phone number (pre-additional area code needs) was 753-2401

Powerflite - 2017-11-11 11:19 AM

I got the filter elements and decal for the 4bbl air cleaner and put it all together. Not sure if super glossy is the look I wanted, but I'll go with it for now. If I re-do it, I may try a semi-gloss instead. But this should look a lot better than that Moroso air cleaner that I had on there. :)

Maybe this could be an option for you:

Edited by 56D500boy 2017-11-11 11:42 AM

(57CoronetWith331ChryslerHemiAndFakedHemiHeadAirCleaner.jpg) (57CoronetWith331ChryslerHemiAndFakedHemiHeadAirCleaner.jpg)

Attachments

----------------

57CoronetWith331ChryslerHemiAndFakedHemiHeadAirCleaner.jpg (269KB - 592 downloads) 57CoronetWith331ChryslerHemiAndFakedHemiHeadAirCleaner.jpg (269KB - 592 downloads)

|

|

| |

|

Expert 5K+

Posts: 9900

Location: Lower Mainland BC | 56D500boy - 2017-11-11 11:40 AM

Powerflite - 2016-03-31 2:19 AM Is that PLeasant 3-2401 an old type of phone number?

P = 7 and L = 5 so the phone number (pre-additional area code needs ) was 753-2401

1801 W Manchester is gone. Replaced by Kim's Mobil Oil station at 1803 (takes the whole corner including what was 1801). Phone 323-758-6233 (so still PLeasant)

Next door shops also have 75n pre-fixes.

Edited by 56D500boy 2017-11-11 12:08 PM

(1813WestManchesterLosAngeles.jpg) (1813WestManchesterLosAngeles.jpg)

Attachments

----------------

1813WestManchesterLosAngeles.jpg (122KB - 593 downloads) 1813WestManchesterLosAngeles.jpg (122KB - 593 downloads)

|

|

| |

|

Expert 5K+

Posts: 9654

Location: So. Cal | 56D500boy - 2017-11-11 9:05 AM

Maybe this could be an option for you:

Nah, I am going for an original look even though the drive-train, wheels & paint aren't original. I decided that I want to eventually swap in a '56 354 motor and I am going to make it look completely stock for 1956. It will be as if someone ordered a transplanted Chrysler motor in their Plymouth. I am calling it the P501.  That means using the stock Chrysler air cleaner and going back to silver valve covers. I will probably use the Dodge "no-name" truck covers that would be more applicable to a Plymouth, and the same covers that they used on the D501. That means using the stock Chrysler air cleaner and going back to silver valve covers. I will probably use the Dodge "no-name" truck covers that would be more applicable to a Plymouth, and the same covers that they used on the D501.

56D500boy - 2017-11-11 9:05 AM

P = 7 and L = 5 so the phone number (pre-additional area code needs) was 753-2401

1801 W Manchester is gone. Replaced by Kim's Mobil Oil station at 1803 (takes the whole corner including what was 1801). Phone 323-758-6233 (so still PLeasant)

Next door shops also have 75n pre-fixes.

That's cool to find out how they worked that. I just remember Andy Griffith calling up Sara and telling her to patch him into Floyd's shop. But with a bigger city like LA, that would be very impractical.

Edited by Powerflite 2017-11-11 3:35 PM

(andy-griffith.jpg) (andy-griffith.jpg)

Attachments

----------------

andy-griffith.jpg (11KB - 623 downloads) andy-griffith.jpg (11KB - 623 downloads)

|

|

| |

|

Expert 5K+

Posts: 9900

Location: Lower Mainland BC | Powerflite - 2017-11-11 3:16 PM

56D500boy - 2017-11-11 9:05 AM

P = 7 and L = 5 so the phone number (pre-additional area code needs) was 753-2401

1801 W Manchester is gone. Replaced by Kim's Mobil Oil station at 1803 (takes the whole corner including what was 1801). Phone 323-758-6233 (so still PLeasant)

Next door shops also have 75n pre-fixes.

That's cool to find out how they worked that. I just remember Andy Griffith calling up Sara and telling her to patch him into Floyd's shop. But with a bigger city like LA, that would be very impractical.

When I was a kid living in Regina, Saskatchewan, the phone number of my parents house was JOrdan 9 - 1523, known later as 569-1523. That was like 60 years ago and I still remember that phone number (long since gone).

The other telephone exchange at the time was LAkeside which included 522 and 527 numbers. So that is why I knew what was up with PLeasant 3 - 2401.

|

|

| |

|

Elite Veteran

Posts: 792

Location: Buena Park, CA | Screws are correct for the firewall tag. And I had to laugh at the P-501 comment. My wife and I were joking when I was looking for a 315 Hemi for our '56 Plymouth. I was also going to do all of the suspension to D500 spec for our "P500". |

|

| |

|

Expert 5K+

Posts: 9654

Location: So. Cal | So those screws are correct for a Los Angeles car too? I know in '57-'58 they used one-way screws in LA only. I am assuming this is a Los Angeles car, but I actually don't know for sure. But the tag codes look like LA codes from '57. |

|

| |

|

Elite Veteran

Posts: 792

Location: Buena Park, CA | Nathan, I was hunting for a picture of the data plate on my LA Built '56 Plymouth and couldn't find one so I will confirm the screws when I get home. I know that my Detroit built '56 Dodge has standard phillips screws. According to build information in the 55-56 Plymouth FSM for a P-29-2 (Savoy w/ V-8): A serial number between 15,873,001 and 22,247,00 = Detroit built; 22,247,001 and 26,552,000 = Evansville; and 26,552,001 - up = Los Angeles. |

|

| |

|

Expert 5K+

Posts: 9654

Location: So. Cal | Thanks for the info Dave. My VIN is 265568XX So this car was an early production build at the LA plant. Last summer one of the freeze plugs rusted a hole into it and started spewing coolant in a high pressure stream - while I was 250 miles away from home, towing a camping trailer on the way back from a family outing. Getting a tow truck for the car, another one for the trailer, and somehow getting all my family back home again is a huge pain in the neck so I was very motivated to make it work. We stopped every 30 miles to let it cool and refill with coolant. It got us home fine and the motor didn't overheat so that was good, but it spewed rusty coolant everywhere and made a big mess in the engine compartment. Now that I have my New Yorker movable, I have the driveway space I need to work on this car and get it going again. I cleaned everything up as much as I could with dish soap. Some of that stuff just doesn't come off - especially from the rubber parts for some reason. But it sure is a lot better than it was.

While I am messing with the motor, I decided to eliminate 35 lbs from my front end by installing the Hot Heads intake and hopefully make it perform a little better too. The carb sits higher than it used to, even with the 1" spacer that I had under it, but not by much. This car has a huge amount of hood clearance so that isn't an issue. I had to fabricate a bracket for the rear generator (now alternator) mount because the new intake doesn't come with anything to support it there, but other than that, it was really easy to swap in place. I also removed the down-draft tube and attached a PCV valve setup to the back of the carburetor. My newly installed '56 Chrysler air cleaner looks a lot better on there than the old Moroso job I used to have! When I get a 354 stroker motor built for it, the valve covers will be painted silver like a stock '56 Chrysler motor, but I am going to leave them gold until then. Now I just need to replace all those freeze plugs!

(FreezePlug Failure Filth.jpg) (FreezePlug Failure Filth.jpg)

(HH Intake & Chrysler AirCleaner.jpg) (HH Intake & Chrysler AirCleaner.jpg)

Attachments

----------------

FreezePlug Failure Filth.jpg (208KB - 585 downloads) FreezePlug Failure Filth.jpg (208KB - 585 downloads)

HH Intake & Chrysler AirCleaner.jpg (233KB - 600 downloads) HH Intake & Chrysler AirCleaner.jpg (233KB - 600 downloads)

|

|

| |

|

Expert 5K+

Posts: 9900

Location: Lower Mainland BC | Nathan: Your engine bay is much improved. Must have been a lot of work. (Nice paint job on the air cleaner BTW)

A couple of questions:

1. Are you running that 56 Chrysler air cleaner as an oil bath or did you convert it to paper like I am trying to do (based on Dave Homstad's hints)?

2. When you removed the old intake did you have much trouble? I have several reasons to remove the intake on my 56 D500 hemi but I am concerned that I will open a can of worms by snapping off a bolt (or two) in the process.

|

|

| |

|

Expert 5K+

Posts: 9654

Location: So. Cal | If you look further up this thread you will see this air cleaner dangling in primer and you can tell that it has been converted to use paper filters. The black paint on it is the same paint I am using to paint the '57 New Yorker, much better quality than the old paint on the oil cap and wire covers. It is a polyurethane paint and is a little thicker than most paints - which is good and bad.

The only issue with removing the intake is that there is water in the ports so you have to drain some of your coolant before you do it. But none of the bolts sit in coolant so I don't think you should have any issues with broken bolts. I removed the intake before I installed the motor because I had to fix a couple of cracks that were in it. So this isn't the first time it has come off. |

|

| |

|

Expert 5K+

Posts: 9900

Location: Lower Mainland BC | Powerflite - 2018-03-13 7:12 PM

If you look further up this thread you will see this air cleaner dangling in primer and you can tell that it has been converted to use paper filters. The black paint on it is the same paint I am using to paint the '57 New Yorker, much better quality than the old paint on the oil cap and wire covers. It is a polyurethane paint and is a little thicker than most paints - which is good and bad.

Thank Nathan.

Okay I went back up the thread and found this:

Powerflite - 2017-05-19 3:13 PM

I was always planning to run dual quads on a 392 hemi for this car. Now I am thinking a single 4 with an original air cleaner would be better. I am even thinking that I may go with a 354 stroker @ 412 cubic inch just to keep it all '56 instead. That's probably more in line with it's current use for pulling my camping trailer & family outings. So I cut up the original air cleaner I had and welded a large 4bbl rim to it from the inside so I could run it with a fuel injection throttle body or a Fi-Tech setup. Watch out when you cut the lids on these things. If you catch the inside on fire, you get to smell what 60 year old burnt horse hair smells like.

Sorry. That primer photo wasn't enough for me to figure out that you converted it. Any chance of a photo of the inside?

Thanks for the paint info. Good to know.

Powerflite - 2018-03-13 7:12 PM

The only issue with removing the intake is that there is water in the ports so you have to drain some of your coolant before you do it. But none of the bolts sit in coolant so I don't think you should have any issues with broken bolts. I removed the intake before I installed the motor because I had to fix a couple of cracks that were in it. So this isn't the first time it has come off.

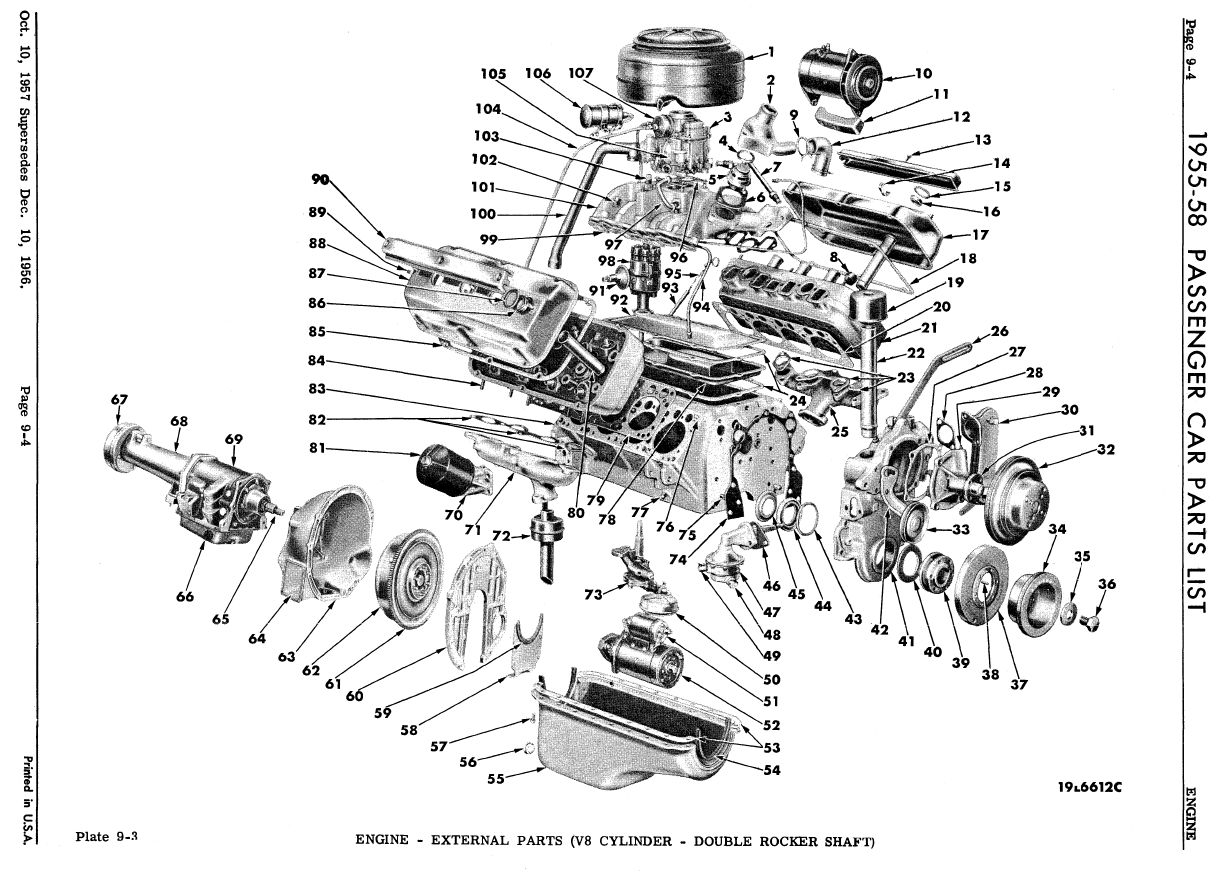

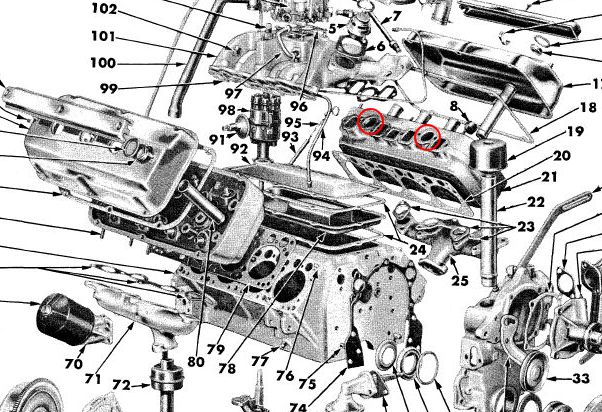

Good news about the intake bolts. However, I am confused about the coolant in the ports (!!??). Might be true of a 392 but I don't think that is true for a Dodge 315 or 325 hemi (which is all good). And then again, I am a hemi newbie.

Edited by 56D500boy 2018-03-13 7:30 PM

(55-57GenericHemiEnginePartsDiagram.jpg) (55-57GenericHemiEnginePartsDiagram.jpg)

(1956DodgeCustomRoyalD500StockEngineBay.jpg) (1956DodgeCustomRoyalD500StockEngineBay.jpg)

Attachments

----------------

55-57GenericHemiEnginePartsDiagram.jpg (199KB - 601 downloads) 55-57GenericHemiEnginePartsDiagram.jpg (199KB - 601 downloads)

1956DodgeCustomRoyalD500StockEngineBay.jpg (345KB - 575 downloads) 1956DodgeCustomRoyalD500StockEngineBay.jpg (345KB - 575 downloads)

|

|

| |

|

Expert 5K+

Posts: 9654

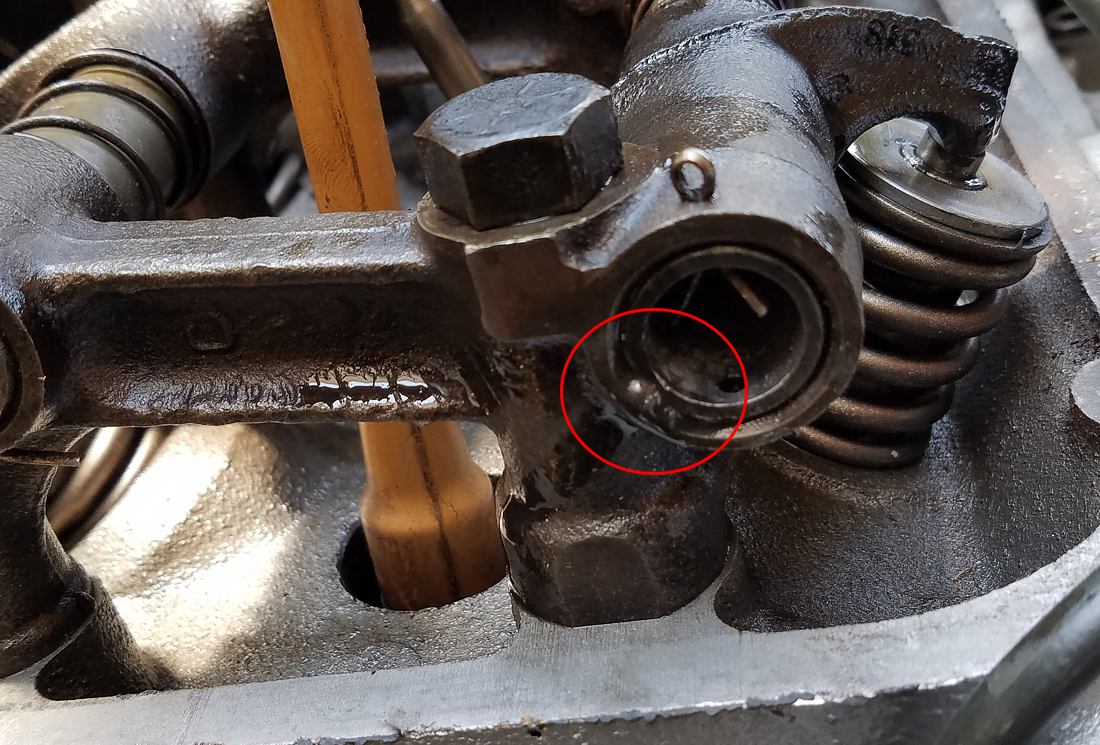

Location: So. Cal | The Dodge has water at the intake too. It is located at the 2 round ports between the intake ports as I have circled. I will post a picture of the inside of the cleaner when I get it apart again.

(55-57GenericHemiEnginePartsDiagram.jpg) (55-57GenericHemiEnginePartsDiagram.jpg)

Attachments

----------------

55-57GenericHemiEnginePartsDiagram.jpg (100KB - 579 downloads) 55-57GenericHemiEnginePartsDiagram.jpg (100KB - 579 downloads)

|

|

| |

|

Expert

Posts: 3033

Location: N.W. Fla. | Powerflite - 2016-03-10 10:58 PM

George, that motor is now slated to go into my '58 New Yorker so it is going back to mostly stock form... I think. Unfortunately, I can't use a stock crossover with those heads because it won't fit. But I am thinking of cutting up a stock one and lengthening it to make it work, but it isn't easy to do if you want to keep the generator mount in the right spot. But I'll give it a shot when I get time to play with it. Wasn't aware that the HH heads wouldn't take the OEM crossover. |

|

| |

|

Expert

Posts: 3033

Location: N.W. Fla. | 56D500boy - 2017-11-11 10:40 AM

Maybe this could be an option for you:

Any idea where the air cleaner decal came from? |

|

| |

|

Expert 5K+

Posts: 9900

Location: Lower Mainland BC | Mopar1 - 2018-03-14 10:35 AM

Any idea where the air cleaner decal came from?

I'm not Nathan but I know of a few places to buy those or similar decals:

https://www.classicindustries.com/shop/1965/dodge/all-models/parts/e...

https://www.ebay.com/itm/Mopar-1962-1963-Stage-I-Max-Wedge-3447-Air-...

|

|

| |

|

Expert 5K+

Posts: 9654

Location: So. Cal | Hello George, the decal came from Ebay. They have an earlier version of it too for '53-'55.

https://www.ebay.com/itm/1956-DODGE-CHRYSLER-PLYMOUTH-DESOTO-IMPERIA...

The Hot Heads won't take the OEM crossover only for the 392. For the 331 or 354, there shouldn't be an issue. |

|

| |

|

Expert 5K+

Posts: 7395

Location: northern germany | nice little bomb. have you ever measured 0-60 times? |

|

| |

|

Expert 5K+

Posts: 9654

Location: So. Cal | Thanks Sid. No, I haven't taken it to the track at all. The motor has never been rebuilt so it still has the original '55 Imperial cam, rings & 8.5:1 pistons in it. Originally it was rated at 250hp, now with the better intake, exhaust and carburetor, it might be around 270hp, but it has also been running a LONG time. Nevertheless, it will easily break the tires loose from a standstill if you nail it, so it is pretty decent, but not as impressive as other cars that were built for power. I mainly use it to tow my camping trailer around and take it on family outings. The low 1st gear of the 700R4 trans is really nice with a trailer behind you in the mountains, but the 11" disc brakes are a little small for the extra weight. I may end up converting the rear to disc and/or going to 12" rotors in the front to handle it better when fully loaded.

(Teardrop Camping.jpg) (Teardrop Camping.jpg)

(SavoyTeardrop.jpg) (SavoyTeardrop.jpg)

Attachments

----------------

Teardrop Camping.jpg (296KB - 623 downloads) Teardrop Camping.jpg (296KB - 623 downloads)

SavoyTeardrop.jpg (240KB - 608 downloads) SavoyTeardrop.jpg (240KB - 608 downloads)

|

|

| |

|

Expert

Posts: 3033

Location: N.W. Fla. | Actually referring to the "331 hemi Head" decal, obviously modeled on the 426 decal. |

|

| |

|

Expert 5K+

Posts: 9900

Location: Lower Mainland BC | Mopar1 - 2018-03-15 11:07 AM

Actually referring to the "331 hemi Head" decal, obviously modeled on the 426 decal.

I'm guessing that was a one-off, just like the one I made for my 315 D500 Hemi. I started with a 426 Hemi decal image.

Edited by 56D500boy 2018-03-15 11:38 AM

(DaveFsD500EngineWithFaked315HemiHeadVinylSticker.jpg) (DaveFsD500EngineWithFaked315HemiHeadVinylSticker.jpg)

Attachments

----------------

DaveFsD500EngineWithFaked315HemiHeadVinylSticker.jpg (174KB - 569 downloads) DaveFsD500EngineWithFaked315HemiHeadVinylSticker.jpg (174KB - 569 downloads)

|

|

| |

|

Expert

Posts: 3033

Location: N.W. Fla. | nice! |

|

| |

|

Expert 5K+

Posts: 9654

Location: So. Cal | I took it to work and took some pictures for the new insurance. Should be much cheaper than what I currently have.

(Savoy At Work.jpg) (Savoy At Work.jpg)

(Savoy At Work Rear.jpg) (Savoy At Work Rear.jpg)

Attachments

----------------

Savoy At Work.jpg (160KB - 564 downloads) Savoy At Work.jpg (160KB - 564 downloads)

Savoy At Work Rear.jpg (234KB - 550 downloads) Savoy At Work Rear.jpg (234KB - 550 downloads)

|

|

| |

|

Expert

Posts: 3967

Location: DFW, TX | That is a great looking ride, man! |

|

| |

|

Expert 5K+

Posts: 9654

Location: So. Cal | Thanks Danny. I have made some mistakes on it along the way, but I like it and it's a fun car. It has recently developed a backfire problem while under load, so I can no longer take it camping until I get that fixed. But it cruises fine still. I am going to try changing the timing chain to see if that fixes it. This motor has never been touched since new. It still had the original spark plug wires on it until a month ago so it's probable that the chain may be loose now. |

|

| |

|

Expert 5K+

Posts: 7395

Location: northern germany | Great car and a good example that aluminum rims don't have to be tasteless on a 50s car. |

|

| |

|

Expert 5K+

Posts: 9654

Location: So. Cal | Thanks Sid, I agree. I wish I had picked 16" instead of 17", but too expensive to change my mind now, so they are staying as-is.

Someone decided that they needed my air cleaner more than I did and stole it from me. Of all the things to steal. What are they going to do with it? I seriously doubt they have a '55-'56 Chrysler product to put it on....but whatever. So now I am making another one. I have a temporary air cleaner on it in the mean time.

This one is heavily dented around the upper edge of it. That's unacceptable because they are usually pretty impossible to fix. However, I cut out the inside of it along the top inner lip and it detached the whole inner structure. I removed the top section of it and notched it at the bottom to be able to remove it from the can. Now I can get inside the outer can, all around to repair the dents. It also allows me to clean up the inner structure to make it look better and allows for better air flow around the filters - especially at the top entrance near the lid. But I will need to create lower mounts to support the tray to the bottom of the can now, and weld them into place. I will also make a flat section to mount to the bottom ring to provide a flat surface for the air filters to sit on instead of the thinner, slanted section that they would have otherwise. I will also try to reduce the carburetor mounting ring extension so the cleaner sits lower than my old one. That was the one thing that bothered me about the way I set up the old one, so this gives me a chance to fix that.

(Oil Bath Cut Out.jpg) (Oil Bath Cut Out.jpg)

Attachments

----------------

Oil Bath Cut Out.jpg (205KB - 594 downloads) Oil Bath Cut Out.jpg (205KB - 594 downloads)

|

|

| |

|

Expert 5K+

Posts: 9900

Location: Lower Mainland BC |

Sorry to hear about the theft Nathan.:( You had done a great job on that air cleaner. Much nicer than my oil to paper conversion or my "Ram Air" versions.

Think of it this way, you have the opportunity to make this next one even better.

Yours:

Mine

Oil to paper:

"Ram Air":

Edited by 56D500boy 2018-09-15 2:11 PM

|

|

| |

|

Expert 5K+

Posts: 9654

Location: So. Cal | I ended up purchasing another air cleaner from the Turlock swap meet in much better shape than the other one, so I decided to use that one instead. I cut it out and welded in the larger carb mount. This time I welded it in about 3/8" lower than before to make it sit lower on the carb. I had to clearance the bottom of the air cleaner in 3 places as a result, but it wasn't bad. I decided not to paint it yet because it doesn't look terrible as it is. I like how it sits on there now, so I'm happy with it.

(AirCleaner 2.0.jpg) (AirCleaner 2.0.jpg)

(56 Chrysler Air Cleaner Lower.jpg) (56 Chrysler Air Cleaner Lower.jpg)

Attachments

----------------

AirCleaner 2.0.jpg (272KB - 505 downloads) AirCleaner 2.0.jpg (272KB - 505 downloads)

56 Chrysler Air Cleaner Lower.jpg (214KB - 529 downloads) 56 Chrysler Air Cleaner Lower.jpg (214KB - 529 downloads)

|

|

| |

|

Expert 5K+

Posts: 9654

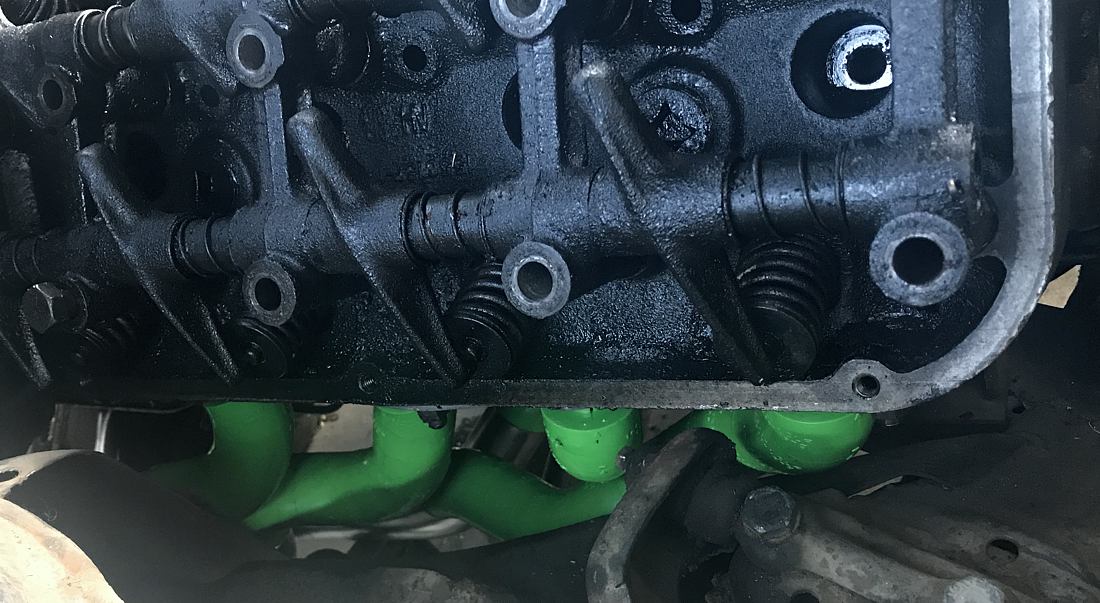

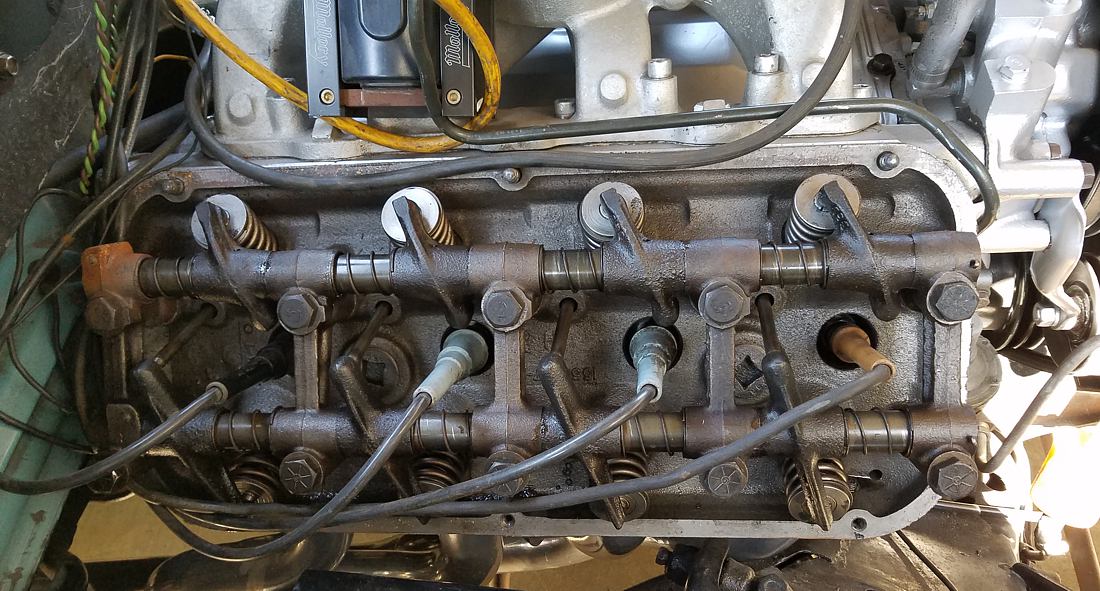

Location: So. Cal | The motor has been losing power any time it is under load, and then will backfire if you try to push it as well. I have determined that the problem has nothing to do with the ignition or the fuel so it is either a problem with the valves, cam, lifters or timing chain. It has been getting worse and makes it impossible to pull a loaded trailer with the car, which is my primary use for it. So I am tearing it down for a refreshing and will rebuild the top end & replace the cam.

When I pulled the valve covers, I was surprised to see that none of the valves were depressed very much. I can also turn the valve springs by hand and they don't seem to be putting much pressure on the valves. What would cause the valves not to be depressed like that? I pulled the lifters and there was a good amount of wear on them, but no gouging or other major issues. Maybe the lifters were leaking down really fast? Or maybe the wear had reduced the lift to a point that it wasn't opening very far? Could any of that cause backfiring under load?

I put up an easy-up to make ti bearable to work out in 105 degree weather without dying.  I had to lift the head with an engine puller too because I don't trust my back to survive such an endeavor. Hemi heads are not to be trifled with. I had to lift the head with an engine puller too because I don't trust my back to survive such an endeavor. Hemi heads are not to be trifled with.

(56Plym Hemi Head Pull.jpg) (56Plym Hemi Head Pull.jpg)

Attachments

----------------

56Plym Hemi Head Pull.jpg (192KB - 520 downloads) 56Plym Hemi Head Pull.jpg (192KB - 520 downloads)

|

|

| |

|

Expert 5K+

Posts: 9654

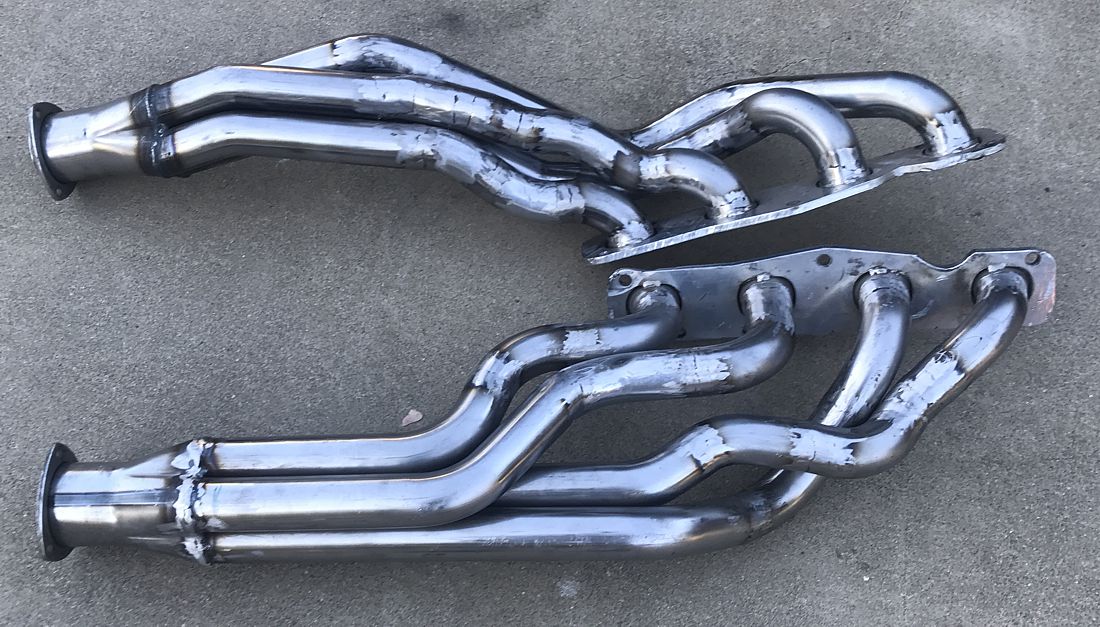

Location: So. Cal | For future reference, this is how I had re-arranged the pipes on the header to make this motor fit well in this car. The upper control arm fits between the two front exhaust pipes so that you can get the motor to sit down low in the engine bay as it should. This is why stock exhaust manifolds don't work well here. Custom pipes are pretty much the only way to go without raising the motor enough to clear the upper control arms. However, this Chinese shorty header dumps straight down as they all do. This requires that you route the exhaust under the steering linkage, giving you something to hit on speed bumps or any time the car bounces when loaded down. Over the course of time, I have flattened mine out pretty good.

So while I am tearing the top end of the motor apart, I am going to build a custom set of long headers, starting from ones made by Patriot Exhaust for a big block in a '57 Chevy. The collector fits along the right side pretty nicely.

(56Plym Shorty Heaader Config Side.jpg) (56Plym Shorty Heaader Config Side.jpg)

(56Plym Shorty Heaader Config Front.jpg) (56Plym Shorty Heaader Config Front.jpg)

(56Plym Hemi-Chevy Collector.jpg) (56Plym Hemi-Chevy Collector.jpg)

Attachments

----------------

56Plym Shorty Heaader Config Side.jpg (211KB - 507 downloads) 56Plym Shorty Heaader Config Side.jpg (211KB - 507 downloads)

56Plym Shorty Heaader Config Front.jpg (123KB - 505 downloads) 56Plym Shorty Heaader Config Front.jpg (123KB - 505 downloads)

56Plym Hemi-Chevy Collector.jpg (135KB - 488 downloads) 56Plym Hemi-Chevy Collector.jpg (135KB - 488 downloads)

|

|

| |

|

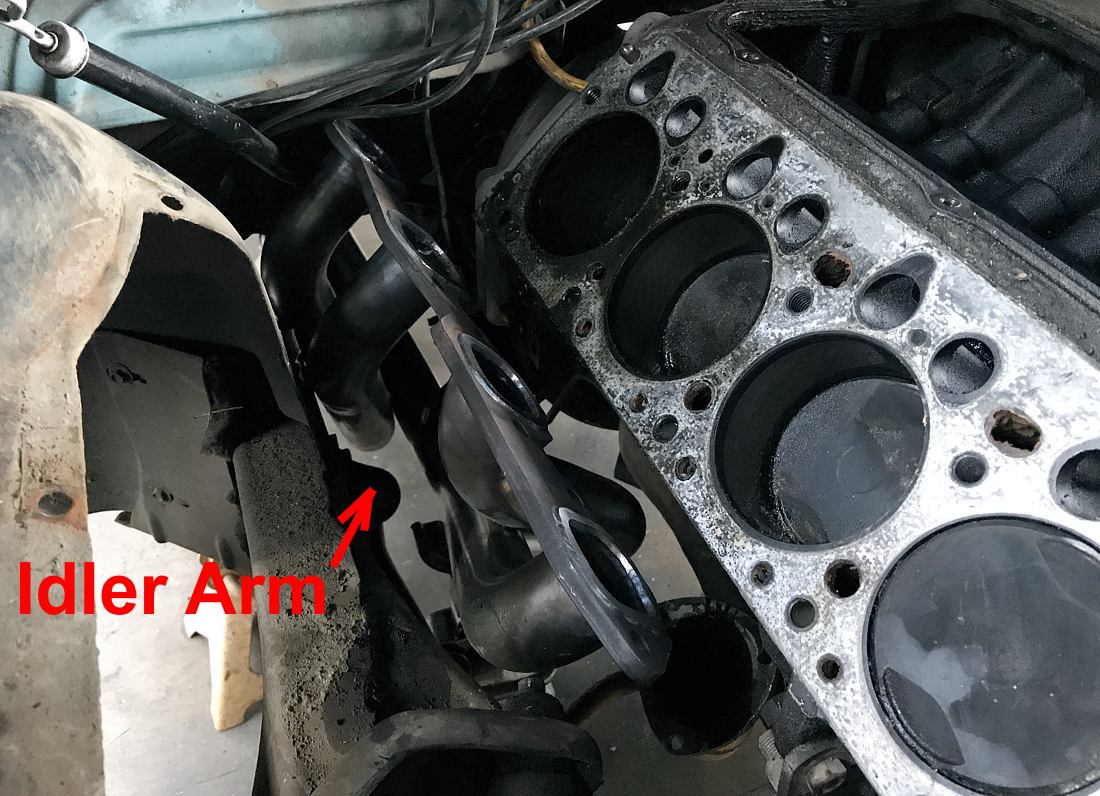

Expert 5K+

Posts: 9654

Location: So. Cal | These '57 Chevy headers are a nice starting point because the bodies are similarly shaped and it uses 1 7/8" tubes with equal spaced ports like the old hemi does. It also uses thick 16 gauge tubes so they shouldn't be obnoxiously loud when finished. They might fit between the idler arm and the trans if I keep the forward ports lined up, but I am thinking I might shorten the rear-most pipes to turn upward before the idler arm (or lengthen the front ones?). This would give it a lot more room around the idler arm. Looks like the best oil filter with this setup would be one that points forward, not downward as I currently have it.

I wasn't able to remove my old headers without removing the head first. There just isn't a lot of room to get to those inner nuts while it's on the motor. I am a little worried about the assembly sequence for these long headers because I wouldn't be able to assemble them off the car first; they are just too big for that. So I'll have to make sure I can access all the mounting nuts somehow ahead of time. These cylinders have surprisingly little wear to them. I was expecting much worse! The front piston is at TDC, so this is what 8.5:1 compression pistons look like for a 331. I am thinking of milling the heads to gain a compression point if I can get away with that.

(56Plym Hemi-Chevy Header.jpg) (56Plym Hemi-Chevy Header.jpg)

Attachments

----------------

56Plym Hemi-Chevy Header.jpg (175KB - 490 downloads) 56Plym Hemi-Chevy Header.jpg (175KB - 490 downloads)

|

|

| |

|

Expert

Posts: 1740

Location: Alaska | I have seen broken valve springs cause a backfire under load, I suppose if they are very weak it might act the same. |

|

| |

|

Veteran

Posts: 296

Location: South Central PA | How about a Hemi powered 55 Wagon.

(Picture 350.jpg) (Picture 350.jpg)

(Picture 354.jpg) (Picture 354.jpg)

(Picture 351.jpg) (Picture 351.jpg)

Attachments

----------------

Picture 350.jpg (174KB - 480 downloads) Picture 350.jpg (174KB - 480 downloads)

Picture 354.jpg (179KB - 481 downloads) Picture 354.jpg (179KB - 481 downloads)

Picture 351.jpg (147KB - 475 downloads) Picture 351.jpg (147KB - 475 downloads)

|

|

| |

|

Expert

Posts: 3033

Location: N.W. Fla. | Powerflite - 2019-07-14 2:54 AM

I am thinking of milling the heads to gain a compression point if I can get away with that. Milling effects the valve geometry. I wouldn't mill unless there's a really good reason for it. Live with the 8.5 until it needs a rebuild & then get the higher C/R pistons. |

|

| |

|

Expert 5K+

Posts: 9654

Location: So. Cal | Thanks a lot for the input, Rolland. This thing has me a little baffled so I am looking for answers. The timing chain seems to me to be the most plausible cause, but checking the slack at the distributor by rotating the motor back and forth, it doesn't seem bad enough to cause what I am experiencing.

George, I knew that milling would affect the intake fit, so you can only go so far before you run into trouble, but I would expect that adjustable push rods should take care of the valve timing. Nevertheless, I am a little worried about valve clearances to the pistons if I start milling because even on a flat top piston, the valves can get pretty close to it with the hemi valve angle.

That '55 wagon looks really nice Bill and I am sure it has more than enough power, but I prefer to use a first gen hemi in these cars. Even though my car is obviously not stock, I try to keep most of it *looking* like it could have been built back in the '50's. I haven't always felt this way about the car so my wheels deviate from that goal a little bit, but I find I like it better that way. I would be more tempted to drop a 426 hemi into my '70 Satellite wagon where it would look more at home. |

|

| |

|

Expert 5K+

Posts: 9654

Location: So. Cal | I got to play with my expensive legos today to design the new headers for the right side. I have them mounted in the collector pipes because the head flange is too un-circular to make the connectors work. The 2 rear pipes are currently too close to each other so I need to cut the forward one down and re-adjust the pipes afterward. I am planning to use the legos to get the parts cut and matched to the design, but then check & mark them first under the car before welding it together. I'll start at the back cylinder and move forward as I go. I thought I had a forward facing oil filter to check the fit, but after digging through my stuff, I apparently don't so I'll have to get one soon. I also need to check the idler arm movement before I get too far...

(Right Header Design Bottom.jpg) (Right Header Design Bottom.jpg)

(Right Header Design Top.jpg) (Right Header Design Top.jpg)

Attachments

----------------

Right Header Design Bottom.jpg (79KB - 461 downloads) Right Header Design Bottom.jpg (79KB - 461 downloads)

Right Header Design Top.jpg (135KB - 465 downloads) Right Header Design Top.jpg (135KB - 465 downloads)

|

|

| |

|

Expert 5K+

Posts: 9654

Location: So. Cal | I haven't had a lot of motivation to work on this project, probably because of the heat; but I made some progress on it yesterday and got the 2 rear-most pipes tacked down into place. Two down, six to go.  Because the design is done, the front two shouldn't take too long, but the trick is to be able to install it without removing the head or lifting the motor first. I think I can achieve that on the right side, but the left is going to be more difficult. Looks like I will be able to use the Chevy & hemi pipes that I cut up and only 2 J-bends for the right side. Maybe only 4 J-bends for the whole set of headers. Because the design is done, the front two shouldn't take too long, but the trick is to be able to install it without removing the head or lifting the motor first. I think I can achieve that on the right side, but the left is going to be more difficult. Looks like I will be able to use the Chevy & hemi pipes that I cut up and only 2 J-bends for the right side. Maybe only 4 J-bends for the whole set of headers.

(56Plym Right Header 2Rear.jpg) (56Plym Right Header 2Rear.jpg)

Attachments

----------------

56Plym Right Header 2Rear.jpg (118KB - 457 downloads) 56Plym Right Header 2Rear.jpg (118KB - 457 downloads)

|

|

| |

|

Expert 5K+

Posts: 9900

Location: Lower Mainland BC | Are you using this? What clever person that was who came up with that.

https://www.trick-tools.com/Icengineworks-1-7-8-inch-Pro-Header-Mode...

|

|

| |

|

Expert 5K+

Posts: 9654

Location: So. Cal | Yes, but they are too expensive for what they are. I paid $650 for a glorified set of legos.  I got the same set as shown in your link but found an older, cheaper price. Can you believe that the price actually went up on these??? Also, it's nice to have a large selection of bends, but if you are piecing it together from J-bends like most home people, there are usually only 1 or 2 radii available to purchase so all those others are just wasted money and garage space. But they have priced it so that buying them in individual packages doesn't save you any money. They do help a whole lot with the design phase of a header build though. I got the same set as shown in your link but found an older, cheaper price. Can you believe that the price actually went up on these??? Also, it's nice to have a large selection of bends, but if you are piecing it together from J-bends like most home people, there are usually only 1 or 2 radii available to purchase so all those others are just wasted money and garage space. But they have priced it so that buying them in individual packages doesn't save you any money. They do help a whole lot with the design phase of a header build though.

Edited by Powerflite 2019-09-03 7:36 PM

|

|

| |

|

Expert 5K+

Posts: 9654

Location: So. Cal | I finished tack welding in the front 2 pipes. The front one was a little more difficult because It had a tendency to want to interfere with the second pipe, but I got it to work well by making a couple of small adjustments. I tried out the forward facing oil filter too, and I can get it on and off, so that's a bonus.  The idler arm in the picture is turned to it's worst case position to ensure it doesn't hit the header. Next, I will try to remove the header without moving the head to see if it is possible or what is required to install it. I suspect that I will need to replace the front 2 studs with bolts to make install easier, but I don't really want to do that. In any case these should be a lot easier to install than the shorties that I had on there. Dumping all the pipes inwards makes it impossible to get to the inner bolts without pulling the motor or the head. I really like how this header turned out. It should be a nice improvement from the previous setup. I am thinking I should pay to have the headers coated after I get them done to help them last longer, although I made them out of 16 gauge so they aren't as likely to rust out as cheap headers. I also removed the left side shorty (by pulling the head off with an engine hoist) to start the prep for making a design on that side. The idler arm in the picture is turned to it's worst case position to ensure it doesn't hit the header. Next, I will try to remove the header without moving the head to see if it is possible or what is required to install it. I suspect that I will need to replace the front 2 studs with bolts to make install easier, but I don't really want to do that. In any case these should be a lot easier to install than the shorties that I had on there. Dumping all the pipes inwards makes it impossible to get to the inner bolts without pulling the motor or the head. I really like how this header turned out. It should be a nice improvement from the previous setup. I am thinking I should pay to have the headers coated after I get them done to help them last longer, although I made them out of 16 gauge so they aren't as likely to rust out as cheap headers. I also removed the left side shorty (by pulling the head off with an engine hoist) to start the prep for making a design on that side.

Edited by Powerflite 2019-09-08 10:48 AM

(56Savoy RtHeader Tacked.jpg) (56Savoy RtHeader Tacked.jpg)

(56Savoy RtHeader Top.jpg) (56Savoy RtHeader Top.jpg)

Attachments

----------------

56Savoy RtHeader Tacked.jpg (122KB - 464 downloads) 56Savoy RtHeader Tacked.jpg (122KB - 464 downloads)

56Savoy RtHeader Top.jpg (203KB - 474 downloads) 56Savoy RtHeader Top.jpg (203KB - 474 downloads)

|

|

| |

|

Expert

Posts: 3033

Location: N.W. Fla. | Powerflite - 2019-07-14 5:09 PM

George, I knew that milling would affect the intake fit, so you can only go so far before you run into trouble,

. The intake can be milled to fit. It's better to leave the C/R alone or adjust with pistons of higher C/R. |

|

| |

|

Expert 5K+

Posts: 9654

Location: So. Cal | Thanks, George, but I am going to leave the bottom end alone because if I have to touch it at all, I am just going to build a 354 and drop it into there. This is a last ditch effort to get this motor to run as well as possible. If I don't like it, it will be pulled & set aside for something else eventually.

The left side exhaust is much more challenging to design well. There isn't any hope to be able to install it without lifting the motor first either so it is much more painful than the right side. The Chevy header that I started with wasn't nearly as ideal of a starting point on the left side either. I had it cut it back almost to the collector, and still, it looks like I will have to place the collector at a small angle instead of horizontal. After it's done, I need to be able to remove the starter as well and hope that it doesn't get heat soaked. Just difficult all around.

(56Ply Left Header Design.jpg) (56Ply Left Header Design.jpg)

Attachments

----------------

56Ply Left Header Design.jpg (163KB - 455 downloads) 56Ply Left Header Design.jpg (163KB - 455 downloads)

|

|

| |

|

Expert 5K+

Posts: 9654

Location: So. Cal | I've had a lot of trial and error with this header design. It is so tight all over, that each pipe is co-dependent on the design of the others next to it. I used an aluminum head to mock it up so that I didn't have to use the engine puller to lift it out every time I needed to.  I had to tack weld my best design of the major part of the front-most pipe to the header in order to make the other lego pipes above it stable enough to design properly, because their weight was causing everything to move around. Also, that pipe comes the closest to the starter so it was more critical and determined where everything else needed to end up. I congratulated myself for giving quite a bit of room around the starter, but that didn't end up being the hard part. The hard part is the 2 rear-most pipes like to share the same space with the steering box. I had to cut the stub at the flange for those as short as I could make them, and this helped a lot, but didn't fix the problem. I was able to barely make it work by bending the rear pipe upward first so that it had more room at the end near the port. But everything is so close around there that I am sure the steering box is going to create its own clearance once the motor vibrates on its mounts. A power steering box doesn't have a chance to work here. Afterward, I had to remove a good portion of the front pipe I had welded, because the pipe next to it needed to bend downward first to be able to enter the port at a better angle. And I'm still not certain I can get this thing in and out without pulling the motor first - even with the head off. I had to tack weld my best design of the major part of the front-most pipe to the header in order to make the other lego pipes above it stable enough to design properly, because their weight was causing everything to move around. Also, that pipe comes the closest to the starter so it was more critical and determined where everything else needed to end up. I congratulated myself for giving quite a bit of room around the starter, but that didn't end up being the hard part. The hard part is the 2 rear-most pipes like to share the same space with the steering box. I had to cut the stub at the flange for those as short as I could make them, and this helped a lot, but didn't fix the problem. I was able to barely make it work by bending the rear pipe upward first so that it had more room at the end near the port. But everything is so close around there that I am sure the steering box is going to create its own clearance once the motor vibrates on its mounts. A power steering box doesn't have a chance to work here. Afterward, I had to remove a good portion of the front pipe I had welded, because the pipe next to it needed to bend downward first to be able to enter the port at a better angle. And I'm still not certain I can get this thing in and out without pulling the motor first - even with the head off.  The starter definitely has to come off, we'll see how it works out. The starter definitely has to come off, we'll see how it works out.

I'm just glad I could do this trial and error design in legos. The right side I could have done OK without them, but this one would have been a total nightmare. At one point I was about to give up and make the pipe 2nd to the rear go around the steering box, but I came to my senses and figured out a way to make it work. It would have probably been easier with smaller pipe like 1 5/8" or maybe 1 3/4", but the 1 7/8" is what most of these headers are made to because of the large exhaust port design on the Chrysler hemi. If I would have forseen all the trouble on this side, I probably would have lived with what I had in there. I was tempted at one point to just put it back in.

(56Plym Left Header Design2.jpg) (56Plym Left Header Design2.jpg)

Attachments

----------------

56Plym Left Header Design2.jpg (182KB - 466 downloads) 56Plym Left Header Design2.jpg (182KB - 466 downloads)

|

|

| |

|

Expert 5K+

Posts: 9900

Location: Lower Mainland BC | Great work there Nathan. Keep it up.

|

|

| |

|

Expert 5K+

Posts: 9900

Location: Lower Mainland BC | Nathan: You might want to check this one out:

1956 Fury with 392 (since 1958 - according to the story):

http://topclassiccarsforsale.com/plymouth/496166-1956-plymouth-fury...

|

|

| |

|

Expert 5K+

Posts: 9654

Location: So. Cal | I know that car very well. It is owned by Ron Swartley, a long-time member on here, and from the old email server. He did the 392 hemi conversion to it back in the late '50's and raced the car. He used cast iron manifolds and raised the motor up higher to prevent them from hitting the control arms. I like the custom header approach better. Also, the 331 or 354 is shorter so it might make that manifold issue even worse than with the 392. |

|

| |

|

Expert

Posts: 3967

Location: DFW, TX | Ron is quite a character. His posts are some of my favorites on this site! He had a lot of fun with his '56 Fury(s) and it shows.

http://forwardlook.net/forums/forums/thread-view.asp?tid=22218 |

|

| |

|

Expert 5K+

Posts: 9654

Location: So. Cal | After redesigning the 2nd to the rear pipe 3 more times, I came to the conclusion that my original design is the best. One of them bent around the steering box more and looked pretty good, but it completely obscured 2 bolts making it very difficult to install them. I welded the header to the frame using the straps that you see and another one at the rear. This keeps it stable to make the designs. Now the 2 rear pipes are finished & tacked into place. Only 2 more to go. These last 2 should be easier to do as there is more room for them.

(56Plym Left Header 2pipes.jpg) (56Plym Left Header 2pipes.jpg)

Attachments

----------------

56Plym Left Header 2pipes.jpg (144KB - 447 downloads) 56Plym Left Header 2pipes.jpg (144KB - 447 downloads)

|

|

| |

|

Expert 5K+

Posts: 9654

Location: So. Cal | I should be further along than I am because I had to redo the 2nd to the rear pipe. It stuck out too far into the space of the pipe going next to it. My welding wasn't as close as my design was able to put it. So I redesigned it to go up more, to give it more room. I finished that, and then finished the 2nd to the front pipe without any issues. I put the rear-most part of the front pipe back in with some mods as well. I just have the front section of the front pipe to go. I should be able to finish it by the end of the week and then take them all out to finish all the welds on them and weld an oxygen sensor bung into one of the collectors too.

(56Plym Left Header 3pipes.jpg) (56Plym Left Header 3pipes.jpg)

(56Plym Left Collector.jpg) (56Plym Left Collector.jpg)

Attachments

----------------

56Plym Left Header 3pipes.jpg (136KB - 462 downloads) 56Plym Left Header 3pipes.jpg (136KB - 462 downloads)

56Plym Left Collector.jpg (153KB - 452 downloads) 56Plym Left Collector.jpg (153KB - 452 downloads)

|

|

| |

|

Expert 5K+

Posts: 9654

Location: So. Cal | Finished the last pipe today. Time to take it out and hope that I can get to all the bolts well enough. Once finished, I will take them to get coated. Hopefully that will help prevent issues with the starter. I may try to install a heat sheild over it as well.

(56Plym Left Header Tacked.jpg) (56Plym Left Header Tacked.jpg)

Attachments

----------------

56Plym Left Header Tacked.jpg (138KB - 446 downloads) 56Plym Left Header Tacked.jpg (138KB - 446 downloads)

|

|

| |

|

Expert 5K+

Posts: 7395

Location: northern germany | Very nice, smooth bends. I build headers before (not as complicated as yours) and I know the work involved!!! |

|

| |

|

Expert 5K+

Posts: 9654

Location: So. Cal | Thanks, yeah, a lot of work - about 2 months worth of weekends. I compromised the port exit a little on the 2nd to rear pipe on the left side -above the steering box, but it wasn't nearly as compromised as the big block chevy headers that I cut up. Those port exits were really sharp. I guess it's easier to build them that way. |

|

| |

|

Expert 5K+

Posts: 9654

Location: So. Cal | After pulling the headers off, I found that it was extremely difficult to get the front lower bolts off with the front pipe so close to it. So I re-routed the front pipe on the left side and cleaned up some of the welds on it. Now I am doing the same on the right side. I also re-adjusted the 3rd pipe a little because it wasn't connected well due to my inability to see it properly under the car. The right header is a little too long to fit as well as I would like on the right side so I am moving the collector up on it about 3 inches as well. Hopefully it will seal well and still fit fine after I am done, but I have good confidence in it. I do all the tack welding with the header fully secured to the head to ensure that the flange remains flat.

(56Plym Rt Side Header Redo.jpg) (56Plym Rt Side Header Redo.jpg)

Attachments

----------------

56Plym Rt Side Header Redo.jpg (156KB - 440 downloads) 56Plym Rt Side Header Redo.jpg (156KB - 440 downloads)

|

|

| |

|

Expert 5K+

Posts: 9654

Location: So. Cal | I think I am finally nearing the close of this never-ending project. I finished all the welding and grinding today and my garage floor is fully covered with metal shavings at this point from all the cutting and grinding over the last 3 months. I just need to weld an Oxygen sensor bung into a collector now. I am thinking of only doing one side, maybe the passenger side but not sure if I would need it on both sides or not. Next week, I'll pay to get them coated on the inside and outside to reduce the heat conduction and prevent rusting. Installation on the right side is pretty straight forward with the front studs replaced by bolts, but the left side requires removing the heads and motor mount bolts and sliding the motor over to get the header in place. Either that, or remove the motor or steering column entirely. It stinks, but is unavoidable due to the proximity of the steering box to the head. You can see in the pic that I also added material to one bolt hole at the back end of the flange due to very poor Chinese tolerances; and I cut a dip into the front part of it to make it easier to get past the upper control arm during installation or removal.

I'm now going to replace the timing chain, cam, lifters, and do a valve job. Hopefully that work won't take as long as building these headers have.

Edited by Powerflite 2019-11-17 1:24 AM

(56Plym Headers Welded.jpg) (56Plym Headers Welded.jpg)

Attachments

----------------

56Plym Headers Welded.jpg (171KB - 493 downloads) 56Plym Headers Welded.jpg (171KB - 493 downloads)

|

|

| |

|

Expert

Posts: 1740

Location: Alaska | That's great Nathan, now that you are practiced up can you make a set for me to put a 354 hemi in my 58 Plymouth? |

|

| |

|

Expert 5K+

Posts: 9654

Location: So. Cal |  I've actually considered making a set of headers for the early hemi in the '57-up cars, but after this experience, I think the 4 bolt manifolds are perfectly fine. I've actually considered making a set of headers for the early hemi in the '57-up cars, but after this experience, I think the 4 bolt manifolds are perfectly fine.  |

|

| |

|

Expert 5K+

Posts: 9654

Location: So. Cal | I've been working on a new emblem for the trunk lid of my car. I want to show that the car is a P501 model from Plymouth. I cut up an F150 emblem to create the 501 script and used a Galaxie 500 emblem to make the P500 version that I would use if I were running a Dodge hemi. The flag emblems are from a '54 Plymouth. I like the P500 script better. It's more suitable for a '56 car, but I still want it to say 501. I'll look at some older stuff and see if I can find anything that would look better.

(P501 Emblems.jpg) (P501 Emblems.jpg)

Attachments

----------------

P501 Emblems.jpg (151KB - 433 downloads) P501 Emblems.jpg (151KB - 433 downloads)

|

|

| |

|

Expert 5K+

Posts: 9654

Location: So. Cal | ...or how about this one with the numbers going vertically?

(P501 Emblem Vertical.jpg) (P501 Emblem Vertical.jpg)

Attachments

----------------

P501 Emblem Vertical.jpg (108KB - 445 downloads) P501 Emblem Vertical.jpg (108KB - 445 downloads)

|

|

| |

|

Expert

Posts: 1740

Location: Alaska | Nathan, not sure I understand your model number. I thought a 56 Plymouth was a P29. |

|

| |

|

Expert 5K+

Posts: 9654

Location: So. Cal |  Yes, of course, but I'm creating a fictional model for what Plymouth would have called it, had they sold their car with a Chrysler hemi installed into it like mine has; hence the P501. Yes, of course, but I'm creating a fictional model for what Plymouth would have called it, had they sold their car with a Chrysler hemi installed into it like mine has; hence the P501. |

|

| |

|

Expert 5K+

Posts: 9654

Location: So. Cal | I'm leaning towards getting rid of the numbers. It's hard to make them look good and fit in well with the '50's style, although the vertical ones aren't bad looking. They can also be confused for engine displacement. I kinda like this from the '54 and '55 Plymouth, but painted up like a '56 would be.

(Plymouth n Flags2.jpg) (Plymouth n Flags2.jpg)

Attachments

----------------

Plymouth n Flags2.jpg (51KB - 436 downloads) Plymouth n Flags2.jpg (51KB - 436 downloads)

|

|

| |

|

Expert 5K+

Posts: 9900

Location: Lower Mainland BC | .

I was curious about the appearance of "Indians" on the Plymouth crest. I found this as part of the History of the Plymouth Colony and the first Thanksgiving:

https://historyofmassachusetts.org/plymouth-colony-history/

|

|

| |

|

Expert 5K+

Posts: 9654

Location: So. Cal | Interesting. I wondered where that little Indian character came from. |

|

| |

|

Expert 5K+

Posts: 9654

Location: So. Cal | I got the headers ceramic coated on the inside and outside by Engineered Applications near downtown LA. They came out great and were cheaper than any other options. The inside coating is a different one than the outside and can withstand higher temperatures. Hopefully this will reduce the heat transfer to the starter and steering box, improve performance, and keep underhood temperatures down.

(56Plym Hemi Headers Coated.jpg) (56Plym Hemi Headers Coated.jpg)

Attachments

----------------

56Plym Hemi Headers Coated.jpg (146KB - 432 downloads) 56Plym Hemi Headers Coated.jpg (146KB - 432 downloads)

|

|

| |

|

Expert

Posts: 3033

Location: N.W. Fla. | Powerflite - 2019-11-23 11:16 AM

Yes, of course, but I'm creating a fictional model for what Plymouth would have called it, had they sold their car with a Chrysler hemi installed into it like mine has; hence the P501. |

|

| |

|

Expert 5K+

Posts: 9654

Location: So. Cal | What would you do for it, other than nothing? |

|

| |

|

Expert

Posts: 3033

Location: N.W. Fla. | Powerflite - 2019-12-02 7:05 PM