| ||

| The Forward Look Network | ||

| ||

Making New Kick Panels From ABS Plastic Using OE panels as templates Making New Kick Panels From ABS Plastic Using OE panels as templatesJump to page : 1 Now viewing page 1 [50 messages per page] | View previous thread :: View next thread |

| Forward Look Technical Discussions -> Body, Glass, Interior and Trim | Message format |

| 56D500boy |

| ||

Exner Expert 10K+ Posts: 10042    Location: Lower Mainland BC | When I got my 1956 Dodge Custom Royal D500 sedan in September 2016, the kick panels were but one of the many things that I knew that I would have to get to and fix/replace eventually. The initial focus was on getting the engine running, then the brakes, then the steering, etc., etc... Somewhere in there, probably last November, while cruising eBay for all things 56 Dodge, I bought a set of kick panels for a 56 Dodge off an well known eBay seller. When I got the panels, I was immediately disappointed by the fact that they just were a painted cardboard and that they didn't fit all that well when I tried them in the car (I know that day, it was the day I finally had the car running and driving Nov. 25th, 2016). Along the way, I also acquired a 28" x 36" inch piece of 1/8" ABS plastic that I had originally intended to use to replace my damaged driver's door panel (ended up using hardboard instead). So today, after "failing" on the new carpet install yesterday (not me per se, the carpet was for a 56 Desoto Fireflite - another story documented elsewhere on this forum), I decided to make new ABS kick panels. So lacking full original kick panels (the right one was terrible and I threw it out months ago, the left one was around but not full sized), I used the eBay kick panels as the starting point. As needed, I trimmed them with scissors and/or taped on pieces of serial box to create a full fit template to use on the ABS. The left cardboard panel required some trimming and some filling out (up to half an inch on the edge that goes into the kick panel retainer bracket by the door edge (also serves as the windlace retainer in that area). The right panel required a lot of trimming and a little bit of filling out. Once I had the cardboard kick panels working (actually installed them temporarily to be sure), I traced them on the textured side of the ABS with a silver Sharpy that I happened to have. (If I did have it, I would have put 2" wide green masking tape on the ABS in the approximate location of where the cut was needed and then use a pen to scribe the template). Once I had the outline, I cut the ABS with my Bosch jig-saw and slightly worn metal blade. Then came a series of trial fits and trims. Because I have a habit of "leaving the line" the ABS was a bit bigger than the template. Better to big and slowly remove material than cut too much and be sorry. Eventually it was close enough that I could shove the back of the new kick panel into the firewall while at the same time warping it enough to get the edge closest to the door into the kick panel retainer. As the photos below show, the end product looks good. At this point, I plan to paint them a Royal Blue (or maybe cover them with a blue Marine Vinyl ). Edited by 56D500boy 2017-10-30 1:25 AM (56DodgeKiclPanelsLeftOriginalDamagedAndNewCardboardModified.jpg) (56DodgeLeftKickPanelModifiedNewCardboardUsedAsTemplateToTraceOntoABSSheet.jpg) (56DodgeLeftKickPanelNewPanelCutOutOfABS.jpg) (56DodgeLeftKickPanelNewABSPanelInPlace.jpg) (56DodgeRightKickPanelAreaAfterTreatmentWithRustConverterAndZeroRustPaint.jpg) (56DodgeRightKickPanelModifiedNewCardboardUsedAsTemplateToTraceOntoABSSheet.jpg) (56DodgeRightKickPanelWithNewABSKickPanelInstalled.jpg) Attachments ----------------  56DodgeKiclPanelsLeftOriginalDamagedAndNewCardboardModified.jpg (244KB - 287 downloads) 56DodgeKiclPanelsLeftOriginalDamagedAndNewCardboardModified.jpg (244KB - 287 downloads) 56DodgeLeftKickPanelModifiedNewCardboardUsedAsTemplateToTraceOntoABSSheet.jpg (175KB - 283 downloads) 56DodgeLeftKickPanelModifiedNewCardboardUsedAsTemplateToTraceOntoABSSheet.jpg (175KB - 283 downloads) 56DodgeLeftKickPanelNewPanelCutOutOfABS.jpg (225KB - 318 downloads) 56DodgeLeftKickPanelNewPanelCutOutOfABS.jpg (225KB - 318 downloads) 56DodgeLeftKickPanelNewABSPanelInPlace.jpg (241KB - 296 downloads) 56DodgeLeftKickPanelNewABSPanelInPlace.jpg (241KB - 296 downloads) 56DodgeRightKickPanelAreaAfterTreatmentWithRustConverterAndZeroRustPaint.jpg (174KB - 290 downloads) 56DodgeRightKickPanelAreaAfterTreatmentWithRustConverterAndZeroRustPaint.jpg (174KB - 290 downloads) 56DodgeRightKickPanelModifiedNewCardboardUsedAsTemplateToTraceOntoABSSheet.jpg (226KB - 313 downloads) 56DodgeRightKickPanelModifiedNewCardboardUsedAsTemplateToTraceOntoABSSheet.jpg (226KB - 313 downloads) 56DodgeRightKickPanelWithNewABSKickPanelInstalled.jpg (228KB - 284 downloads) 56DodgeRightKickPanelWithNewABSKickPanelInstalled.jpg (228KB - 284 downloads) | ||

| |||

| brdtee |

| ||

Veteran Posts: 264     Location: Pieksamaki, Finland, Europe | Looking good! I have the same work ahead, still not sure what material to use but I was at first thinking a thick waterproof cardboard that they use in advertising signs and cover it with thin vinyl before painting it with black matching the door panel. One thing I'm still uncertain is whether to have a layer of soundproofing material on the back side of the kick panels and door panels. | ||

| |||

| Powerflite |

| ||

Expert 5K+ Posts: 9787          Location: So. Cal | I like it too. Although, I am planning to mount speakers there first. | ||

| |||

| 56D500boy |

| ||

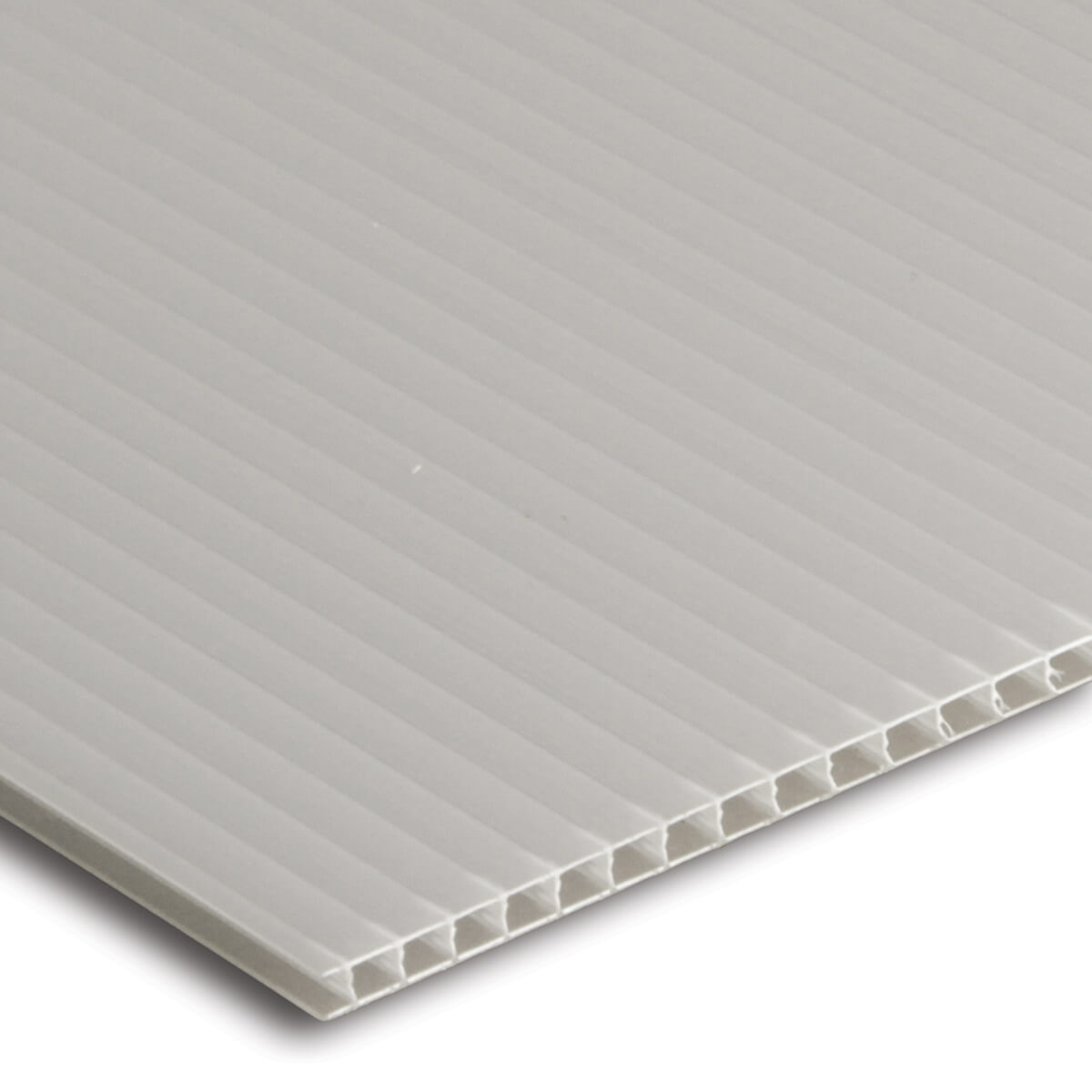

Exner Expert 10K+ Posts: 10042    Location: Lower Mainland BC | The material that they typically use for signs is Coroplast, a corrugated plastic product. I think it is too thick to work as a kick panel material.  | ||

| |||

| brdtee |

| ||

Veteran Posts: 264     Location: Pieksamaki, Finland, Europe | 56D500boy - 2017-11-22 7:14 PM The material that they typically use for signs is Coroplast, a corrugated plastic product. I think it is too thick to work as a kick panel material. Yes this is def. too thick material. There are variety of different materials available, I was referring to a non-corrugated thick cardboard which is waterproof and only about 2 mm thick. Been using that on some event signage myself. | ||

| |||

| 56D500boy |

| ||

Exner Expert 10K+ Posts: 10042    Location: Lower Mainland BC | brdtee - 2017-11-22 12:47 PM There are variety of different materials available, I was referring to a non-corrugated thick cardboard which is waterproof and only about 2 mm thick. Been using that on some event signage myself. The ABS I used was 1/8" thick (about 3 mm). One side was shiny smooth and the other has a "leather"-like texture. | ||

| |||

| 56D500boy |

| ||

Exner Expert 10K+ Posts: 10042    Location: Lower Mainland BC | Yesterday in a 57 Chrysler thread, I joked about the two-tone kick panels in the 57 and then made another joke about maybe trimming my new ABS kick panels like that. Today I found a photo of a 55 St. Regis and those bashtards stole my design!!! I was only 2 in 1953 when they did the design and I didn't reveal it until 64 years later but hey they stole my design. LOL. The 57:  My idea (revealed yesterday after incubating for 64 years): The 55 St. Regis - even has the stainless strip (who knew?) | ||

| |||

| 56D500boy |

| ||

Exner Expert 10K+ Posts: 10042    Location: Lower Mainland BC | Found another trimmed 55 Chrysler kick panel photo at allpar Edited by 56D500boy 2017-12-16 5:40 PM (1955_Chrysler_NewYorkerDeluxe-hardtop_dashboard_kickpanel_large.jpg) Attachments ----------------  1955_Chrysler_NewYorkerDeluxe-hardtop_dashboard_kickpanel_large.jpg (245KB - 266 downloads) 1955_Chrysler_NewYorkerDeluxe-hardtop_dashboard_kickpanel_large.jpg (245KB - 266 downloads) | ||

| |||

| coronetx2 |

| ||

Veteran Posts: 197     Location: Mid Michigan | I did my 56 dodge kick panels with black sheet ABS plastic a couple years ago worked great. Also used it to make the headliner panel for my 61 Plymouth Fury. Used a heat gun to mold/form them and then bonded perforated vinyl on them it worked very well. | ||

| |||

| 56D500boy |

| ||

Exner Expert 10K+ Posts: 10042    Location: Lower Mainland BC | coronetx2 - 2017-12-17 7:31 PM I did my 56 dodge kick panels with black sheet ABS plastic a couple years ago worked great. Also used it to make the headliner panel for my 61 Plymouth Fury. Used a heat gun to mold/form them and then bonded perforated vinyl on them it worked very well. That was brave of you to tackle the Fury headliner in ABS. The stuff I had was pretty stiff. Did you cover the kick panels in vinyl or just paint? How have they stood up? | ||

| |||

| coronetx2 |

| ||

Veteran Posts: 197     Location: Mid Michigan | I left them black door panels are black and white and the carpet is black. When I did my 56 lancer I was on a very tight budget | ||

| |||

| 56D500boy |

| ||

Exner Expert 10K+ Posts: 10042    Location: Lower Mainland BC | While I am in the final stages of installing my carpet (so I get the seats back in the car), I have gotten back to the kick panel project. Using this as my "guide": I am going to use two of my extra pieces of armrest trim to create the "chrome" divider bar. This: (56DodgeABSKickPanelWithHalfInchMaskingTapeToMarkTheChromeBarLocation.jpg) (BackSideOfArmRestTrimAndABSKickPanel.jpg) (ArmRestTrimLayingOverTheHalfInchMaskingTapeLocationMockUp.jpg) Attachments ----------------  56DodgeABSKickPanelWithHalfInchMaskingTapeToMarkTheChromeBarLocation.jpg (195KB - 273 downloads) 56DodgeABSKickPanelWithHalfInchMaskingTapeToMarkTheChromeBarLocation.jpg (195KB - 273 downloads) BackSideOfArmRestTrimAndABSKickPanel.jpg (234KB - 266 downloads) BackSideOfArmRestTrimAndABSKickPanel.jpg (234KB - 266 downloads) ArmRestTrimLayingOverTheHalfInchMaskingTapeLocationMockUp.jpg (227KB - 269 downloads) ArmRestTrimLayingOverTheHalfInchMaskingTapeLocationMockUp.jpg (227KB - 269 downloads) | ||

| |||

| 56D500boy |

| ||

Exner Expert 10K+ Posts: 10042    Location: Lower Mainland BC | Finished off the carpet install and before I put the front seat in, I added the vinyl to the previously painted right front ABS kick panel. Then I added a section of straightened armrest trim at the joint between the upper painted area and the lower vinyl area (vinyl is the stuff I am using when I redo the door panels). Looks like despite my best efforts getting the trim lined up with the door panel trim, I will have to adjust the "new" kick panel trim at bit. However, in general, it looks fairly close to my original concept though so I am happy enough. Photos from today: Edited by 56D500boy 2018-05-28 10:47 PM | ||

| |||

| Powerflite |

| ||

Expert 5K+ Posts: 9787          Location: So. Cal | Looks really good. I am wondering if I could adapt a newer molded carpet to the car instead of dealing with this cut & sewn stuff that doesn't really work that well. | ||

| |||

| 56D500boy |

| ||

Exner Expert 10K+ Posts: 10042    Location: Lower Mainland BC | Powerflite - 2018-05-29 11:17 AM Looks really good. I am wondering if I could adapt a newer molded carpet to the car instead of dealing with this cut & sewn stuff that doesn't really work that well. Cut and sewn probably works better when the set you receive is actually supposed to fit your car, i.e. a 56 Plymouth, etc. NOT a 56 Desoto into a 56 Dodge. | ||

| |||

| Jump to page : 1 Now viewing page 1 [50 messages per page] |

| Search this forum Printer friendly version E-mail a link to this thread |

| (Delete all cookies set by this site) | |