Veteran

Posts: 145

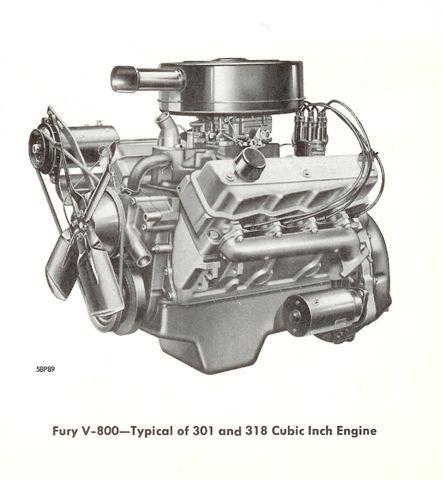

Location: Denver, Colorado, USA | I've jumped into the YouTube fray with a couple videos that might be of interest to this group. This particular video is the first installment in my series on A-block engine rebuilding. The video covers complete engine disassembly for 1956 - 1967 A-block engines including cleaning out the rocker-arm shafts, reconditioning lightly worn rocker arm tips, and addressing removal and plugging of the oil filter bypass valve found on many pre-1962 A-blocks. The video is also applicable to disassembling LA 273, 318, 340, and 360 since the short-block assemblies are nearly identical with only minor differences in the disassembly process, although only the 273 and some 340 use cast ductile rocker arms like the A-block.

My machinist and I are almost finished with the cylinder heads after we hogged out the valves to 2.02" intake 1.625" exhaust with stainless race valves and after I did a full port job on them. We rough-bored the block .020" to make sure it will clean up at .030" and decked it true, but I have three more weeks left before the custom forged dome pistons are supposed to be finished (the manufacturer was 10 weeks out when I placed the order). Those pistons will put the dynamic compression at an optimal 8.15 (10.8 static). SCAT's lead sales tech has my forged 4" stroker crank and connecting rods sitting beside his desk waiting on the pistons for them to balance the rotating assembly. Once I get the assembly, my machinist and I can torque-plate hone the block, and back at my house I'll clearance the block for the stroker setup and begin the final cleaning and assembly. I'll be documenting that entire process and will create another video along with an article on my website. If you subscribe to my YouTube channel, you'll get pinged when I post the cleaning/blueprinting/assembly video. Hopefully the video helps some people on their projects or at the very least is interesting. |

1956 - 1967 A-block Engine Rebuild Video for Poly 277, 301, 303, 313, 318, 326

1956 - 1967 A-block Engine Rebuild Video for Poly 277, 301, 303, 313, 318, 326